Page 251 - Managing Global Warming

P. 251

210 Managing Global Warming

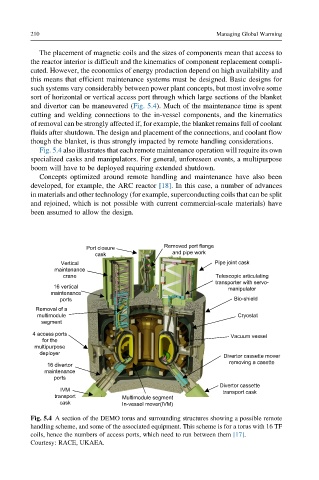

The placement of magnetic coils and the sizes of components mean that access to

the reactor interior is difficult and the kinematics of component replacement compli-

cated. However, the economics of energy production depend on high availability and

this means that efficient maintenance systems must be designed. Basic designs for

such systems vary considerably between power plant concepts, but most involve some

sort of horizontal or vertical access port through which large sections of the blanket

and divertor can be maneuvered (Fig. 5.4). Much of the maintenance time is spent

cutting and welding connections to the in-vessel components, and the kinematics

of removal can be strongly affected if, for example, the blanket remains full of coolant

fluids after shutdown. The design and placement of the connections, and coolant flow

though the blanket, is thus strongly impacted by remote handling considerations.

Fig. 5.4 also illustrates that each remote maintenance operation will require its own

specialized casks and manipulators. For general, unforeseen events, a multipurpose

boom will have to be deployed requiring extended shutdown.

Concepts optimized around remote handling and maintenance have also been

developed, for example, the ARC reactor [18]. In this case, a number of advances

in materials and other technology (for example, superconducting coils that can be split

and rejoined, which is not possible with current commercial-scale materials) have

been assumed to allow the design.

Removed port flange

Port closure

and pipe work

cask

Vertical Pipe joint cask

maintenance

crane Telescopic articulating

transporter with servo-

16 vertical

manipulator

maintenance

ports Bio-shield

Removal of a

multimodule Cryostat

segment

4 access ports

Vacuum vessel

for the

multipurpose

deployer

Divertor cassette mover

removing a casette

16 divertor

maintenance

ports

Divertor cassette

IVM transport cask

transport Multimodule segment

cask In-vessel mover(IVM)

Fig. 5.4 A section of the DEMO torus and surrounding structures showing a possible remote

handling scheme, and some of the associated equipment. This scheme is for a torus with 16 TF

coils, hence the numbers of access ports, which need to run between them [17].

Courtesy: RACE, UKAEA.