Page 292 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 292

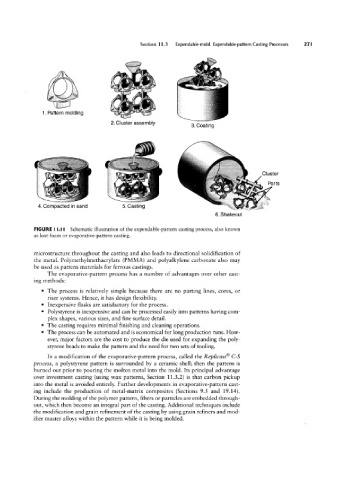

1. Pattern molding

,» ‘é Section 11.3 Expendable-mold, Expendable-pattern Casting Processes

' '

I

A

3. Coating

....

.....

2. Cluster assembly

., .

Parts

4. Compacted in sand 5. Casting Cluster

6. Shakeout

FIGURE l.| I Schematic illustration of the expendable-pattern casting process, also known

I

as lost-foam or evaporative-pattern casting.

microstructure throughout the casting and also leads to directional solidification of

the metal. Polymethylmethacrylate (PMMA) and polyalkylene carbonate also may

be used as pattern materials for ferrous castings.

The evaporative-pattern process has a number of advantages over other cast-

ing methods:

° The process is relatively simple because there are no parting lines, cores, or

riser systems. Hence, it has design flexibility.

' Inexpensive flasks are satisfactory for the process.

° Polystyrene is inexpensive and can be processed easily into patterns having com-

plex shapes, various sizes, and fine surface detail.

° The casting requires minimal finishing and cleaning operations.

° The process can be automated and is economical for long production runs. How-

ever, major factors are the cost to produce the die used for expanding the poly-

styrene beads to make the pattern and the need for two sets of tooling.

In a modification of the evaporative-pattern process, called the Replicc1st® C-S

process, a polystyrene pattern is surrounded by a ceramic shell; then the pattern is

burned out prior to pouring the molten metal into the mold. Its principal advantage

over investment casting (using Wax patterns, Section II.3.2) is that carbon pickup

into the metal is avoided entirely. Further developments in evaporative-pattern cast-

ing include the production of metal-matrix composites (Sections 9.5 and 19.14).

During the molding of the polymer pattern, fibers or particles are embedded through-

out, which then become an integral part of the casting. Additional techniques include

the modification and grain refinement of the casting by using grain refiners and mod-

ifier master alloys within the pattern while it is being molded.