Page 288 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 288

f __ S 26

Expendable-mold, Permanent-pattern Casting Processes

Section 11.2

HWS Q

Core prints

Core prints

AVV: ,,5,

%

Gate

Mechanical drawing of part Cope pattern plate Drag pattern plate Core boxes

"

(H) (D) (C) (d)

/ee

2

Sprue si. Z/

,-

4

*%

»

\-

§' Flask ~ 'vlt " Cope after ramming “V ,,i,

r§§§fi?:¥¥#

"W

with sand and

Core halves removing perrern, Drag ready Drag after

pasted together Cope ready for sand sprue’ and risers for sand removing pattern

(G) (f) (Q) (li) (I)

\\\T”f \

pins

7 fr""“ 1

Drag with core Cope and drag assembled Casting as removed Casting ready

set in place and ready for pouring from mold; heat treated for shipment

(i) (K) (l)

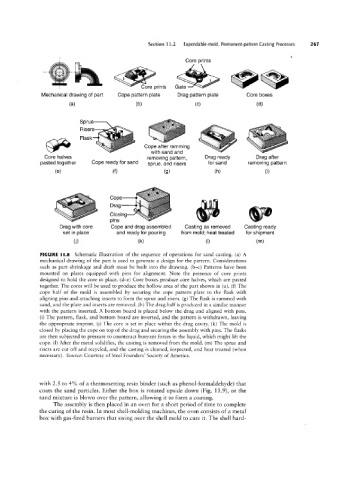

FIGURE ||.8 Schematic illustration of the sequence of operations for sand casting. (a) A

mechanical drawing of the part is used to generate a design for the pattern. Considerations

such as part shrinkage and draft must be built into the drawing. (b-c) Patterns have been

mounted on plates equipped with pins for alignment. Note the presence of core prints

designed to hold the core in place. (d-e) Core boxes produce core halves, which are pasted

together. The cores will be used to produce the hollow area of the part shown in (a). (f) The

cope half of the mold is assembled by securing the cope pattern plate to the flask with

aligning pins and attaching inserts to form the sprue and risers. (g) The flask is rammed with

sand, and the plate and inserts are removed. (h) The drag half is produced in a similar manner

with the pattern inserted. A bottom board is placed below the drag and aligned with pins.

(i) The pattern, flask, and bottom board are inverted, and the pattern is withdrawn, leaving

the appropriate imprint. (j) The core is set in place within the drag cavity. (k) The mold is

closed by placing the cope on top of the drag and securing the assembly with pins. The flasks

are then subjected to pressure to counteract buoyant forces in the liquid, which might lift the

cope. (l) After the metal solidifies, the casting is removed from the mold. (m) The sprue and

risers are cut off and recycled, and the casting is cleaned, inspected, and heat treated (when

necessary). Source: Courtesy of Steel Founders’ Society of America.

with 2.5 to 4% of a thermosetting resin binder (such as phenol-formaldehyde) that

coats the sand particles. Either the box is rotated upside down (Fig. 11.9), or the

sand mixture is blown over the pattern, allowing it to form a coating.

The assembly is then placed in an oven for a short period of time to complete

the curing of the resin. In most shell-molding machines, the oven consists of a metal

box with gas-fired burners that swing over the shell mold to cure it. The shell hard-