Page 285 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 285

264 Chapter 11 Metal-Casting Processes and Equipment

S\ 7. Vents, which are placed in molds to carry off gases produced

Cope side

when the molten metal comes into contact with the sand in the

Plate mold and the core. Vents also exhaust air from the mold cavity

as the molten metal flows into the mold.

Patterns. Patterns are used to mold the sand mixture into the shape

Drag side of the casting and may be made of wood, plastic, or metal. The selec-

tion of a pattern material depends on the size and shape of the casting,

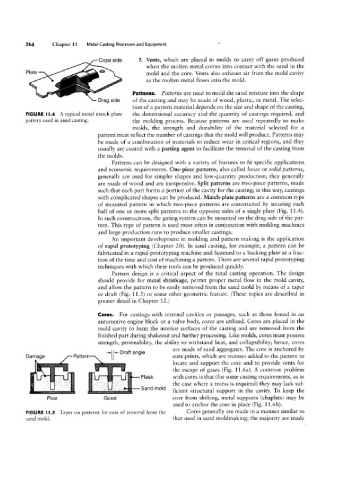

FIGURE ll.4 A typical metal match-plate the dimensional accuracy and the quantity of castings required, and

pattern used in sand casting. the molding process. Because patterns are used repeatedly to make

molds, the strength and durability of the material selected for a

pattern must reflect the number of castings that the mold will produce. Patterns may

be made of a combination of materials to reduce wear in critical regions, and they

usually are coated with a parting agent to facilitate the removal of the casting from

the molds.

Patterns can be designed with a variety of features to fit specific applications

and economic requirements. One-piece patterns, also called loose or solid patterns,

generally are used for simpler shapes and low~quantity production; they generally

are made of wood and are inexpensive. Split patterns are two-piece patterns, made

such that each part forms a portion of the cavity for the casting; in this way, castings

with complicated shapes can be produced. Match-plate patterns are a common type

of mounted pattern in which two-piece patterns are constructed by securing each

half of one or more split patterns to the opposite sides of a single plate (Fig. 11.4).

In such constructions, the gating system can be mounted on the drag side of the pat-

tern. This type of pattern is used most often in conjunction with molding machines

and large production runs to produce smaller castings.

An important development in molding and pattern making is the application

of rapid prototyping (Chapter 20). In sand casting, for example, a pattern can be

fabricated in a rapid-prototyping machine and fastened to a backing plate at a frac-

tion of the time and cost of machining a pattern. There are several rapid prototyping

techniques with which these tools can be produced quickly.

Pattern design is a critical aspect of the total casting operation. The design

should provide for metal shrinkage, permit proper metal flow in the mold cavity,

and allow the pattern to be easily removed from the sand mold by means of a taper

or draft (Fig. 11.5 ) or some other geometric feature. (These topics are described in

greater detail in Chapter 12.)

Damage

Cores.

For castings with internal cavities or passages, such as those found in an

automotive engine block or a valve body, cores are utilized. Cores are placed in the

mold cavity to form the interior surfaces of the casting and are removed from the

finished part during shakeout and further processing. Like molds, cores must possess

strength, permeability, the ability to withstand heat, and collapsibility; hence, cores

are made of sand aggregates. The core is anchored by

core prints, which are recesses added to the pattern to

locate and support the core and to provide vents for

Pattern T( (47 Draft angle the escape of gases (Fig. 11.6a). A common problem

»`,s, Flask with cores is that (for some casting requirements, as in

. ...,. " lf Sand mold the case where a recess is required) they may lack suf-

ficient structural support in the cavity. To keep the

Good

Poor ' ...,.,, i ‘ core from shifting, metal supports (chaplets) may be

used to anchor the core in place (Fig. 11.6b).

FIGURE I l.5 Taper on patterns for ease of removal from the Cores generally are made in a manner similar to

sand mold. that used in sand moldmaking; the majority are made