Page 281 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 281

2 0 Chapter 11 Metal-Casting Processes and Equipment

,,;~*"Y,.»;"

ww

(H) (D)

(C) (d)

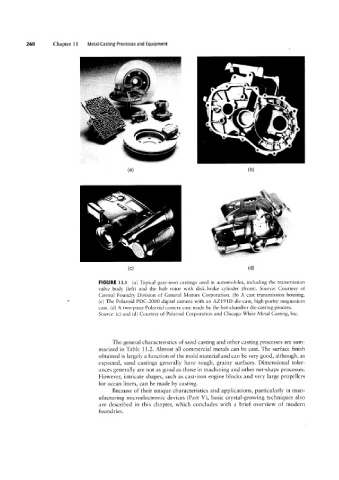

FIGURE |l.I (a) Typical gray-iron castings used in automobiles, including the transmission

valve body (left) and the hub rotor with disk-brake cylinder (front). Source: Courtesy of

Central Foundry Division of General Motors Corporation. (b) A cast transmission housing.

(c) The Polaroid PDC-2000 digital camera with an AZ19lD die-cast, high-purity magnesium

case. (d) A two-piece Polaroid camera case made by the hot-chamber die-casting process.

Source: (C) and (d) Courtesy of Polaroid Corporation and Chicago White Metal Casting, Inc.

The general characteristics of sand casting and other casting processes are sum-

marized in Table 11.2. Almost all commercial metals can be cast. The surface finish

obtained is largely a function of the mold material and can be very good, although, as

expected, sand castings generally have rough, grainy surfaces. Dimensional toler-

ances generally are not as good as those in machining and other net-shape processes.

However, intricate shapes, such as cast-iron engine blocks and very large propellers

for ocean liners, can be made by casting.

Because of their unique characteristics and applications, particularly in man-

ufacturing microelectronic devices (Part V), basic crystal-growing techniques also

are described in this chapter, which concludes With a brief overview of modern

foundries.