Page 286 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 286

Section 11.2 Expandable-mold, Permanent-pattern Castlng Processes 2

\

Cavity Core Cavity Chaplet Core

-~<'1 1

I '-‘im »‘ »<`»~"» `-.\.»‘ ,<

/‘ ' '3‘?%l9?=”E

‘Arif “¢‘- if .f"ff

>”ss

Core

p \ \ Partmg lme Ti* Core

. ,_,;,:, ,VY;_,,V,,,,,=, V,,,,,,,V _

- 'air ~ ;;ft»/.,1 ,,q:,.‘; .¢}"}.§,>., ;

yéfgligx

.M-;

.~;;;;~,.<»i§tg.\,_.g,.;'¢;;f

;,<”‘;_¢§ ~';;€{. 1567 ) e

(H) (D)

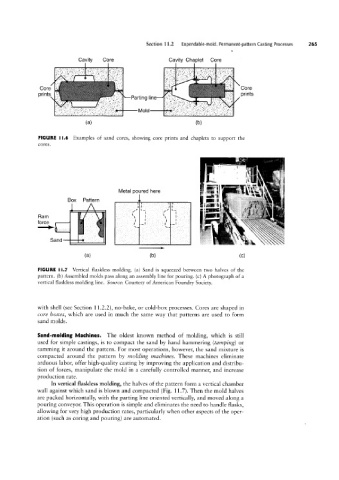

FIGURE ll.6 Examples of sand cores, showing core prints and chaplets to support the

cores.

.ii,hfiii.§Q'

Metal poured here

A /',~, /'

Sand I up

Box

Pattern

p& p 1

.tp_ 1

ik

Ram ij jp “ y 1%

1

_,L liyfiy’

_rt

force , pp,s. - t tes f,’ tpspp .ip ling,

i_

(3) (D) (C)

FIGURE ll.7 Vertical flaskless molding. (a) Sand is squeezed between two halves of the

pattern. (b) Assembled molds pass along an assembly line for pouring. (c) A photograph ofa

vertical flaskless molding line. Source: Courtesy of American Foundry Society.

with shell (see Section 11.2.2), no-bake, or cold-box processes. Cores are shaped in

core boxes, which are used in much the same way that patterns are used to form

sand molds.

Sand-molding Machines. The oldest known method of molding, which is still

used for simple castings, is to compact the sand by hand hammering (tamping) or

ramming it around the pattern. For most operations, however, the sand mixture is

compacted around the pattern by molding machines. These machines eliminate

arduous labor, offer high-quality casting by improving the application and distribu-

tion of forces, manipulate the mold in a carefully controlled manner, and increase

production rate.

In vertical flaskless molding, the halves of the pattern form a vertical chamber

wall against which sand is blown and compacted (Fig. 11.7). Then the mold halves

are packed horizontally, with the parting line oriented vertically, and moved along a

pouring conveyor. This operation is simple and eliminates the need to handle flasks,

allowing for very high production rates, particularly when other aspects of the oper-

ation (such as coring and pouring) are automated.