Page 284 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 284

Vent

Section 11.2 Expendable-mold, Permanent-pattern Casting Processes 263

J

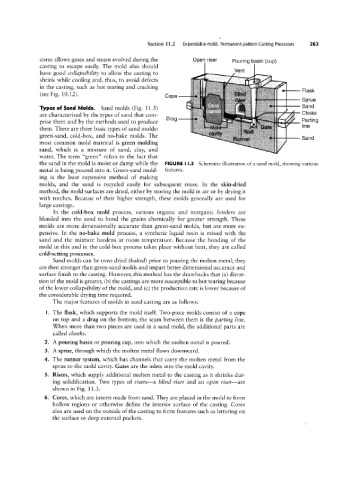

cores allows gases and steam evolved during the ODGH “Ser Pouring basin (cup)

casting to escape easily. The mold also should i=

have good collapsibility to allow the casting to Cope - Z

shrink while cooling and, thus, to avoid defects .gi 1~§§~Q,f£jl5j£j-_f;j»,f»

in the casting, such as hot tearing and cracking

(see Fig. 10.12). Flask

Pfue

Types of Sand Molds. Sand molds (Fig. 11.3) Sand

T ‘“

are characterized by the types of sand that com- Q Choke

""

“

them. There are three basic types of sand molds: ~ me t.

P

Drag -hff-»»» _,,,

arm

.emu *~h-.ZT25f3--

-

prise them and by the methods used to produce

green-sand, cold-box, and no-bake molds. The a.

»_ Sand

most common mold material is green molding

sand, which is a mixture of sand, clay, and

water. The term “green” refers to the fact that

the sand in the mold is moist or damp while the FIGURE l.3 Schematic illustration of a sand mold, showing various

l

metal is being poured into it. Green-sand mold- features.

ing is the least expensive method of making

molds, and the sand is recycled easily for subsequent reuse. In the skin-dried

method, the mold surfaces are dried, either by storing the mold in air or by drying it

with torches. Because of their higher strength, these molds generally are used for

large castings.

In the cold-box mold process, various organic and inorganic binders are

blended into the sand to bond the grains chemically for greater strength. These

molds are more dimensionally accurate than green-sand molds, but are more ex-

pensive. ln the no-bake mold process, a synthetic liquid resin is mixed with the

sand and the mixture hardens at room temperature. Because the bonding of the

mold in this and in the cold-box process takes place without heat, they are called

cold-setting processes.

Sand molds can be oven dried (baked) prior to pouring the molten metal; they

are then stronger than green-sand molds and impart better dimensional accuracy and

surface finish to the casting. However, this method has the drawbacks that (a) distor-

tion of the mold is greater, (b) the castings are more susceptible to hot tearing because

of the lower collapsibility of the mold, and (c) the production rate is lower because of

the considerable drying time required.

The major features of molds in sand casting are as follows:

I. The flask, which supports the mold itself. Two-piece molds consist of a cope

on top and a drag on the bottom; the seam between them is the parting line.

When more than two pieces are used in a sand mold, the additional parts are

called cbee/es.

2. A pouring basin or pouring cup, into which the molten metal is poured.

3. A sprue, through which the molten metal flows downward.

4. The runner system, which has channels that carry the molten metal from the

sprue to the mold cavity. Gates are the inlets into the mold cavity.

5. Risers, which supply additional molten metal to the casting as it shrinks dur-

ing solidification. Two types of risers-a blind riser and an open riser-are

shown in Fig. 11.3.

6. Cores, which are inserts made from sand. They are placed in the mold to form

hollow regions or otherwise define the interior surface of the casting. Cores

also are used on the outside of the casting to form features such as lettering on

the surface or deep external pockets.