Page 128 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 128

Section 4.4 The Iron Carbon System

joining. Although there are various types of solders, tin-lead solders are commonly

used for general applications; they have compositions ranging from 5% Pb-95 % Sn

to 70% Pb-30% Sn. Each composition has its own melting point.

4.4 The Iron-Carbon System

Steels and cast irons are represented by the iron-carbon binary system. Commercially

pure iron contains up to 0.008% C, steels up to 2.11% C, and cast irons up to

6.67% C, although most cast irons contain less than 4.5% C. In this section the

iron-carbon system is described, including the techniques employed to evaluate and

modify the properties of these important materials for specific applications.

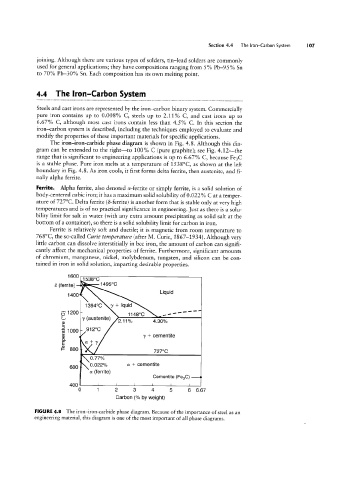

The iron-iron-carbide phase diagram is shown in Fig. 4.8, Although this dia-

gram can be extended to the right-to 100% C (pure graphite); see Fig. 4.12~the

range that is significant to engineering applications is up to 6.67% C, because Fe3C

is a stable phase. Pure iron melts at a temperature of 1538°C, as shown at the left

boundary in Fig. 4.8. As iron cools, it first forms delta ferrite, then austenite, and fi-

nally alpha ferrite.

Ferrite. Alpha ferrite, also denoted a-ferrite or simply ferrite, is a solid solution of

body-centered cubic iron; it has a maximum solid solubility of 0.022% C at a temper-

ature of 727°C. Delta ferrite (5-ferrite) is another form that is stable only at very high

temperatures and is of no practical significance in engineering. just as there is a solu-

bility limit for salt in Water (With any extra amount precipitating as solid salt at the

bottom of a container), so there is a solid solubility limit for carbon in iron.

Ferrite is relatively soft and ductile; it is magnetic from room temperature to

768°C, the so-called Curie temperature (after M. Curie, 1867-1934). Although very

little carbon can dissolve interstitially in bcc iron, the amount of carbon can signifi-

cantly affect the mechanical properties of ferrite. Furthermore, significant amounts

of chromium, manganese, nickel, molybdenum, tungsten, and silicon can be con-

tained in iron in solid solution, imparting desirable properties.

160° 1538°C O

6 (ferrite) 1495 C

1400 Liquid

1394°C 1' + liquid

,»*"""'

§l2O°` .1 114s°C

5 I’ (a“S‘e'“' el 2.11% 4.30%

1% 1000 - 9I2°C

3, y + cementite

E' oz -I- 'y

19 soo 727.0

0.77%

600 0_022% a + cementite

CY (ferrite) Cementite (Fe3C) -¢

O 1 2 3 4 5 6 6.67

Carbon (% by weight)

FIGURE 4.8 The iron-iron-carbide phase diagram. Because of the importance of steel as an

engineering material, this diagram is one of the most important of all phase diagrams.