Page 241 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 241

220 Chapter 9 Composite Materials: Structure, General Properties, and Applications

TABLE 9.2

Typical Properties of Reinforcing Fibers

Tensile strength Elastic modulus Density

Type (MPa) (GPa) (kg/m3 ) Relative cost

Boron 3500 2600 Highest

Carbon

High strength 3000 1900 Low

High modulus 2000 1900 Low

Glass

E-type 3500 2480 Lowest

S-type 4600 2540 Lowest

Kevlar

29 2800 1440 High

49 2800 1440 High

129 3200 1440 High

Nextel

312 1630 2700 High

610 2770 3960 High

Spectra

900 2270 970 High

1000 2670 970 High

2000 3240 970 High

Alumina (Al2O3) 1900 3900 High

1

Silicon carbide 3500 3200 High

Matrix lg fl Tungsten diameter

Note: These properties vary significantly depending on the material and method of preparation.

L gv-g Kevlar fibers

'yi

i’r"frs

Graphite fibers of 0.012 mm

Boron diameter

5,

0.1 mm

Mali”

(G) (D)

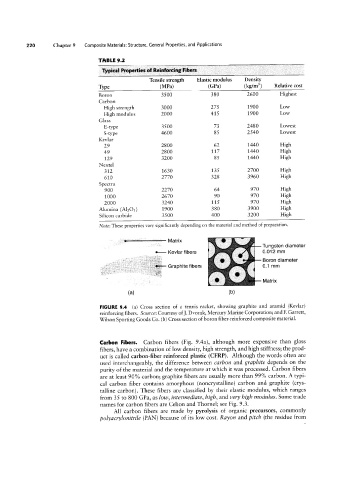

FIGURE 9.4 (a) Cross section of a tennis racket, showing graphite and aramid (Kevlar)

reinforcing fibers. Source: Courtesy of ]. Dvorak, Mercury Marine Corporation; and F. Garrett,

Wilson Sporting Goods Co. (b) Cross section of boron fiber-reinforced composite material.

Carbon Fibers. Carbon fibers (Fig. 9.4a), although more expensive than glass

fibers, have a combination of low density, high strength, and high stiffness; the prod-

uct is called carbon-fiber reinforced plastic (CFRP). Although the words often are

used interchangeably, the difference between carbon and graphite depends on the

purity of the material and the temperature at which it was processed. Carbon fibers

are at least 90% carbon; graphite fibers are usually more than 99% carbon. A typi-

cal carbon fiber contains amorphous (noncrystalline) carbon and graphite (crys-

talline carbon). These fibers are classified by their elastic modulus, which ranges

from 35 to 800 GPa, as lou/, intermediate, high, and 1/ery high modulus. Some trade

names for carbon fibers are Celion and Thornel; see Fig. 9.3.

All carbon fibers are made by pyrolysis of organic precursors, commonly

polyacrylonitrile (PAN) because of its low cost. Rayon and pitch (the residue from