Page 337 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 337

- \\ 0 Introduction 3

Section 13 1

~e 1

Hot strip

Pickling and

Cold strip

oiling

1

i,}!‘\`!llu

\ ';:42':':`; X Irgél

Slab A Skelp >

Welded pipe

l

»»1i:u@!» ,

Steel plates

Plate

,Jw (4 *

el.;

_I

"`

Hot-rolled bars Cold-drawn bars ‘

Continuous I3 'l‘@ Q \ pup; H V,

~-_

casting or

A #if**> VY:-;§U;;Tg Wire

ingots p

Billet Rods '

Seamless pipe

Tube rounds

._ ,F Structural shapes

l'g§s&.

B'°°m -»»l§-ll»t!»ll~

Rails

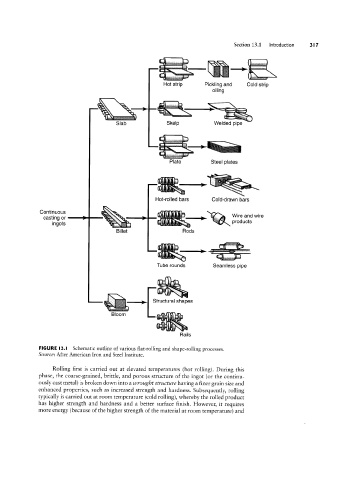

FIGURE I3.l Schematic outline of various flat-rolling and shape-rolling processes.

Source: After American Iron and Steel Institute.

Rolling first is carried out at elevated temperatures (hot rolling). During this

phase, the coarse-grained, brittle, and porous structure of the ingot (or the continu-

ously cast metal) is broken down into a wrought structure having a finer grain size and

enhanced properties, such as increased strength and hardness. Subsequently, rolling

typically is carried out at room temperature (cold rolling), whereby the rolled product

has higher strength and hardness and a better surface finish. However, it requires

more energy (because of the higher strength of the material at room temperature) and