Page 339 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 339

Section 13.2 The Flat rolllng Process 3

h = (Top roll removed) Vf \ F? /<»l (Bottom roll removed)

/1

/

>;,>

/

WO

Cl

“T rerrrrrr No-sup W

R°" ygyy

P°"“

Friction forces

Roll "“ i Entry_l Floll l_Exit Torque

“Y hr zone gap,LI zone

(H) (D)

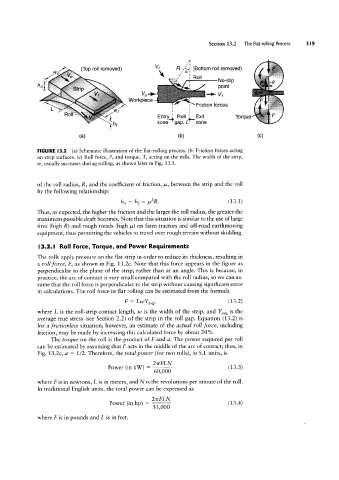

FIGURE l3.2 (a) Schematic illustration of the flat-rolling process. (b) Friction forces acting

on strip surfaces. (c) Roll force, F, and torque, T, acting on the rolls. The width of the strip,

w, usually increases during rolling, as shown later in Fig. 13.5.

of the roll radius, R, and the coefficient of friction, ILL, between the strip and the roll

by the following relationship:

/3, - 13) = MR. (13.1)

Thus, as expected, the higher the friction and the larger the roll radius, the greater the

maximum possible draft becomes. Note that this situation is similar to the use of large

tires (high R) and rough treads (high ,u.) on farm tractors and off-road earthmoving

equipment, thus permitting the vehicles to travel over rough terrain without skidding.

l3.2.I Roll Force, Torque, and Power Requirements

The rolls apply pressure on the flat strip in order to reduce its thickness, resulting in

a roll force, F, as shown in Fig. 13.2c. Note that this force appears in the figure as

perpendicular to the plane of the strip, rather than at an angle. This is because, in

practice, the arc of contact is very small compared with the roll radius, so we can as-

sume that the roll force is perpendicular to the strip without causing significant error

in calculations. The roll force in flat rolling can be estimated from the formula

P = Lu/Yavg, (13.2)

where L is the roll-strip contact length, 1/U is the width of the strip, and Yavg is the

average true stress (see Section 2.2) of the strip in the roll gap. Equation (13.2) is

for a frictionless situation; however, an estimate of the actual roll force, including

friction, may be made by increasing this calculated force by about 20%.

The torque on the roll is the product of F and a. The power required per roll

can be estimated by assuming that F acts in the middle of the arc of contact; thus, in

Fig. 13.2c, a = L/2. Therefore, the total power (for two rolls), in S.I. units, is

2 PLN

Power (in 1<\x/) = £366 (13.3)

where F is in newtons, L is in meters, and N is the revolutions per minute of the roll.

In traditional English units, the total power can be expressed as

Power (in hp) = H06 (13.4)

21-rFLN

where F is in pounds and L is in feet.