Page 341 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 341

Section 13.2

1 Backup rolls

hYdVaU|iC

Backing bearing

mechanism 7 ff; The Flat-rolling Process 32|

Screw or

[ _

i»- Housing

fiiiil

Chocks § § " Work rolls ff

W. _“_ VT W

Backup rolls

intermediate roli (D) Housing (C)

:::::: -.

(H)

,V

shape during rolling. just as a straight beam deflects under a

D""e" '°"

BGHVWIQ Shaft

Driven I'0||

Second

Smp

thicker at its center than at its edges (crown). The usual

Driven roll W ,, 5, Q if ' Efgimediate roll

@ ; <§= 5 °""°"

l ease W

~

Because of the forces acting on them, rolls undergo changes in ,` Rolls

(d)

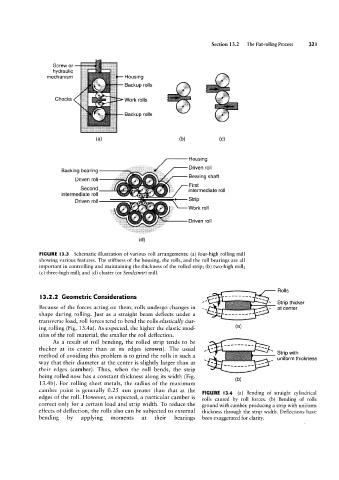

FIGURE I3.3

Schematic illustration of various roll arrangements: (a) four-high rolling mill

showing various features. The stiffness of the housing, the rolls, and the roll bearings are all

important in controlling and maintaining the thickness of the rolled strip; (b) two-high mill;

(c) three-high mill; and (d) cluster (or Sendzimir) mill.

" ' `

ttrtrtt ....

method of avoiding this problem is to grind the rolls in such a if , Strip thicker

l3.2.2 Geometric Considerations

at Centgr

transverse load, roll forces tend to bend the rolls elastically dur-

'iii

ing rolling (Fig. 13.4a). As expected, the higher the elastic mod-

(al

ulus of the roll material, the smaller the roll deflection.

As a result of roll bending, the rolled strip tends to be § `

way that their diameter at the center is slightly larger than at , ` . ifillérvéltllhickness

their edges (camber). Thus, when the roll bends, the strip N ~

,,,__,,,,

being rolled now has a constant thickness along its width (Fig. (b)

13.4b). For rolling sheet metals, the radius of the maximum

camber point is generally 0.25 mm greater than that at the

FIGURE l3.4 (a) Bending of straight cylindrical

edges of the roll. However, as expected, a particular camber is rolls caused by roll forces. (b) Bending of rolls

correct only for a certain load and strip width. To reduce the ground with camber, producing a strip with uniform

effects of deflection, the rolls also can be subjected to external thickness through the strip width. Deflections have

bending by applying moments at their bearings been exaggerated for clarity.