Page 346 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 346

Chapter 13 Metal-Rolling Processes and Equipment

Coll storage Take-up reel Mill stands with roll diameters ranging from 0.6 to 1.4 m.

In the three-high mill (reversing mill,

Fig. 13.3c) the direction of material move-

ment is reversed after each pass, using eleva-

tor mechanisms and various manipulators.

The plate being rolled, which may weigh as

much as 145 metric tons, is raised repeatedly

to the upper roll gap, rolled, then lowered to

the lower roll gap, rolled, and so on.

Four-high mills (Fig. 13.3a) and cluster

mills (Sendzimir or Z mill, Fig. 13.3d) are

based on the principle that small-diameter

rolls lower roll forces (because of small roll-

strip contact area) and power requirements

and reduce spreading. Moreover, when worn

or broken, small rolls can be replaced at lower

cost than can large ones. On the other hand,

small rolls deflect more under roll forces and

have to be supported by other large-diameter

Operator controls

rolls, as is done in four-high and cluster mills.

Although the cost of a Sendzimir mill facility

FIGURE I3 I0 View of a rolling mill. Source: Courtesy of lspat Inland.

can be very high, it is particularly suitable for

cold rolling thin sheets of high-strength metals. Common rolled widths in this mill are

0.66 m, with a maximum of 1.5 m.

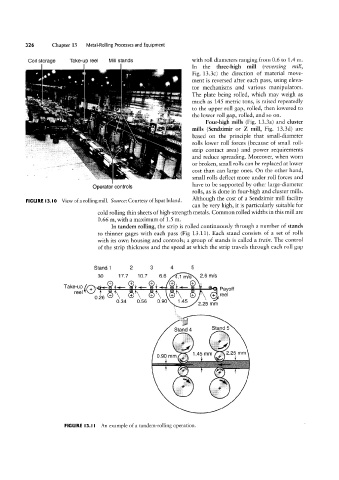

In tandem rolling, the strip is rolled continuously through a number of stands

to thinner gages with each pass (Fig 13.11). Each stand consists of a set of rolls

with its own housing and controls; a group of stands is called a train. The control

of the strip thickness and the speed at which the strip travels through each roll gap

Stand 1 2 3 4 5

30 17.7 10.7 6.6 4_1 m/S 2.6 m/s

Take};.1§ <_ X G) r Payoff

_

\ \ \ 9 \

0.26 J fee'

0.34 0.56 0.90 1.45 2 25 mm

Sf?,Qf§ 5

stand 4 25

G* Yiii

a ti ”

VV_V__V

`f;_

l

FIGURE l3.l I An example of a tandem-rolling operation.