Page 351 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 351

Mandrel

Section 13.5 Various Rolling Processes and Mills

stress Rolls

Cavity rod

void initiation

(H) (D) (C)

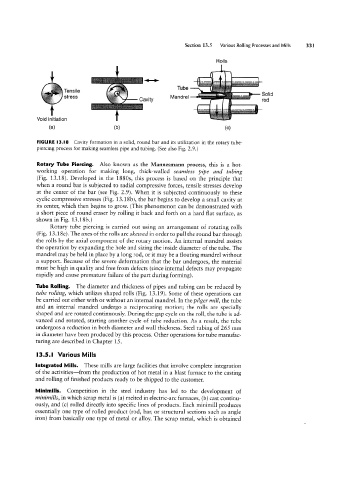

FIGURE l3.I8 Cavity formation in a solid, round bar and its utilization in the rotary tube-

piercing process for making seamless pipe and tubing. (See also Fig. 2.9.)

Rotary Tube Piercing. Also known as the Mannesmann process, this is a hot-

working operation for making long, thick-Walled seamless pipe and tubing

(Fig. l3.18). Developed in the 1880s, this process is based on the principle that

when a round bar is subjected to radial compressive forces, tensile stresses develop

at the center of the bar (see Fig. 2.9). When it is subjected continuously to these

cyclic compressive stresses (Fig. 13.18b), the bar begins to develop a small cavity at

its center, which then begins to grow. (This phenomenon can be demonstrated with

a short piece of round eraser by rolling it back and forth on a hard flat surface, as

shown in Fig. 13.18b.)

Rotary tube piercing is carried out using an arrangement of rotating rolls

(Fig. 13.18c). The axes of the rolls are skewed in order to pull the round bar through

the rolls by the axial component of the rotary motion. An internal mandrel assists

the operation by expanding the hole and sizing the inside diameter of the tube. The

mandrel may be held in place by a long rod, or it may be a floating mandrel without

a support. Because of the severe deformation that the bar undergoes, the material

must be high in quality and free from defects (since internal defects may propagate

rapidly and cause premature failure of the part during forming).

Tube Rolling. The diameter and thickness of pipes and tubing can be reduced by

tube rolling, which utilizes shaped rolls (Fig. 13.19). Some of these operations can

be carried out either with or without an internal mandrel. In the pilger mill, the tube

and an internal mandrel undergo a reciprocating motion; the rolls are specially

shaped and are rotated continuously. During the gap cycle on the roll, the tube is ad-

vanced and rotated, starting another cycle of tube reduction. As a result, the tube

undergoes a reduction in both diameter and Wall thickness. Steel tubing of 265 mm

in diameter have been produced by this process. Other operations for tube manufac-

turing are described in Chapter 15.

l3.5.I Various Mills

Integrated Mills. These mills are large facilities that involve complete integration

of the activities-from the production of hot metal in a blast furnace to the casting

and rolling of finished products ready to be shipped to the customer.

Minimills. Competition in the steel industry has led to the development of

minimills, in which scrap metal is (a) melted in electric-arc furnaces, (b) cast continu-

ously, and (c) rolled directly into specific lines of products. Each minimill produces

essentially one type of rolled product (rod, bar, or structural sections such as angle

iron) from basically one type of metal or alloy. The scrap metal, which is obtained