Page 348 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 348

2 Chapter 13 Metal-Rolling Processes and Equipment

Shaped roll /¥

-> Q-finished

Ejector

Workp|ece Vszw ,e g / P

<a> <b>

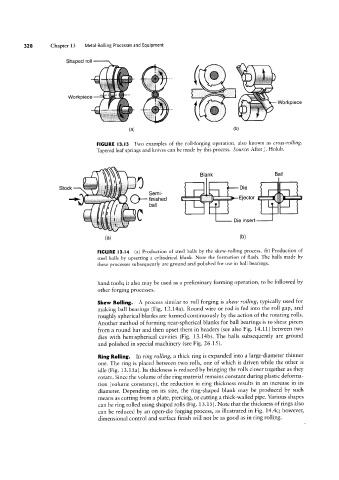

FIGURE l3.I3 Two examples of the roll-forging operation, also known as cross-rolling.

Tapered leaf springs and knives can be made by this process. Source: After ]. Holub.

\ \ Blank Die F Ball

z.; fl; ,,f;; |. fa ls"

em|-

S‘°°'< ~=f"'nn“ S ' ‘

_

_

=f=~ ='

fi/

l

-

V1

(H) (D)

FIGURE l3.l4 (a) Production of steel balls by the skew-rolling process. (b) Production of

steel balls by upsetting a cylindrical blank. Note the formation of flash. The balls made by

these processes subsequently are ground and polished for use in ball bearings.

hand tools; it also may be used as a preliminary forming operation, to be followed by

other forging processes.

Slcew Rolling. A process similar to roll forging is skew rolling, typically used for

making ball bearings (Fig. 13.14a). Round wire or rod is fed into the roll gap, and

roughly spherical blanks are formed continuously by the action of the rotating rolls.

Another method of forming near-spherical blanks for ball bearings is to shear pieces

from a round bar and then upset them in headers (see also Fig. 14.11) between two

dies with hemispherical cavities (Fig. 13.l4b). The balls subsequently are ground

and polished in special machinery (see Fig. 26.15).

Ring Rolling. In ring rolling, a thick ring is expanded into a large-diameter thinner

one. The ring is placed between two rolls, one of which is driven while the other is

idle (Fig. 13.15a). Its thickness is reduced by bringing the rolls closer together as they

rotate. Since the volume of the ring material remains constant during plastic deforma-

tion (volume constancy), the reduction in ring thickness results in an increase in its

diameter. Depending on its size, the ring-shaped blank may be produced by such

means as cutting from a plate, piercing, or cutting a thick-walled pipe. Various shapes

can be ring rolled using shaped rolls (Fig. 13.15). Note that the thickness of rings also

can be reduced by an open-die forging process, as illustrated in Fig. 14.4c; however,

dimensional control and surface finish will not be as good as in ring rolling.