Page 352 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 352

->

_' . J T/grbdrel v( Wtbrkpiece

2 Chapter 13 Metal-Rolling Processes and Equipment

R

||

7,

'

Workpiece 1 Mandrel rod > '“" { * Rod

(H) (D)

Il s

t _, > - Workpiece

Of P'9C9 mi r

\

Mfféfii

(C) (d)

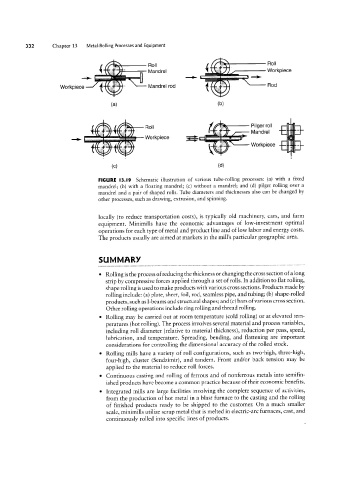

FIGURE I3.l9 Schematic illustration of various tube-rolling processes: (a) with a fixed

mandrel; (b) with a floating mandrel; (c) Without a mandrel; and (d) pilger rolling over a

mandrel and a pair of shaped rolls. Tube diameters and thicknesses also can be changed by

other processes, such as drawing, extrusion, and spinning.

locally (to reduce transportation costs), is typically old machinery, cars, and farm

equipment. Minimills have the economic advantages of lovv-investment optimal

operations for each type of metal and product line and of low labor and energy costs.

The products usually are aimed at markets in the mill’s particular geographic area.

SUMMARY

° Rolling is the process of reducing the thickness or changing the cross section of a long

strip by compressive forces applied through a set of rolls. In addition to flat rolling,

shape rolling is used to make products with various cross sections. Products made by

rolling include: (a) plate, sheet, foil, rod, seamless pipe, and tubing; (b) shape-rolled

products, such as I-beams and structural shapes; and (c) bars of various cross section.

Other rolling operations include ring rolling and thread rolling.

° Rolling may be carried out at room temperature (cold rolling) or at elevated tem-

peratures (hot rolling). The process involves several material and process variables,

including roll diameter (relative to material thickness), reduction per pass, speed,

lubrication, and temperature. Spreading, bending, and flattening are important

considerations for controlling the dimensional accuracy of the rolled stock.

° Rolling mills have a variety of roll configurations, such as tvvo-high, three-high,

four-high, cluster (Sendzimir), and tandem. Front and/or back tension may be

applied to the material to reduce roll forces.

° Continuous casting and rolling of ferrous and of nonferrous metals into semifin-

ished products have become a common practice because of their economic benefits.

° Integrated mills are large facilities involving the complete sequence of activities,

from the production of hot metal in a blast furnace to the casting and the rolling

of finished products ready to be shipped to the customer. On a much smaller

scale, minimills utilize scrap metal that is melted in electric-arc furnaces, cast, and

continuously rolled into specific lines of products.