Page 350 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 350

gy;

330 Chapter 13 Metal-Rolling Processes and Equipment

.~

f

Blank

F

é

*fl/~<' A E; izé* *W* Moving die " “'”

Stationary die

Threaded part

la) lb)

Workpiece

Work rest

Force

Moving

cylindrical die

ld)

(C) *lx

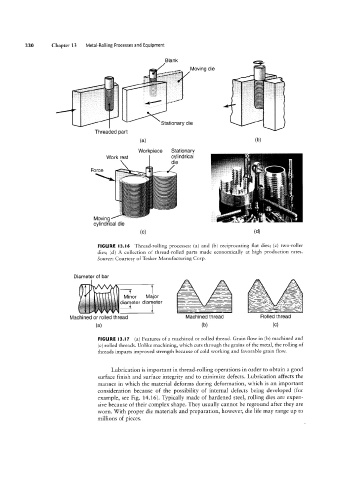

FIGURE I3.|6 Thread-rolling processes: (a) and (b) reciprocating flat dies; (c) two-roller

dies; (d) A collection of thread-rolled parts made economically at high production rates.

Source: Courtesy of Tesker Manufacturing Corp.

i

;

Diameter of bar an ~»~_§~\ /

_

it

Minor Major °; :-;_+ /2-Tl`~€>_

-_;-;_-

diameter diameter

Machined or rolled thread l Machined thread Rolled thread

(8) (D) (C)

FIGURE l3.l7 (a) Features of a machined or rolled thread. Grain flow in (b) machined and

(c) rolled threads. Unlike machining, which cuts through the grains of the metal, the rolling of

threads imparts improved strength because of cold Working and favorable grain flow.

Lubrication is important in thread-rolling operations in order to obtain a good

surface finish and surface integrity and to minimize defects. Lubrication affects the

manner in which the material deforms during deformation, which is an important

consideration because of the possibility of internal defects being developed (for

example, see Fig. 14.16). Typically made of hardened steel, rolling dies are expen-

sive because of their complex shape. They usually cannot be reground after they are

Worn. With proper die materials and preparation, however, die life may range up to

millions of pieces.

_nf

F<<l<i<i<<<l<`,.

~v=-'i