Page 358 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 358

Die

338 Chapter 14 Metal-Forging Processes and Equipment

S_

D|

V§ '

Workpiece [71 h2 E Friction forces

Barrelmg

(H) (D) (C)

FIGURE l4.3 (a) Solid cylindrical billet upset between two flat dies. (b) Uniform deformation

of the billet without friction. (c) Deformation with friction. Note barreling of the billet caused

by friction forces at the billet-die interfaces.

Die Workpigli Die

Workpiece

Die Q. i i f ‘

`

Workpiece Die

Die

(H) (b) (C)

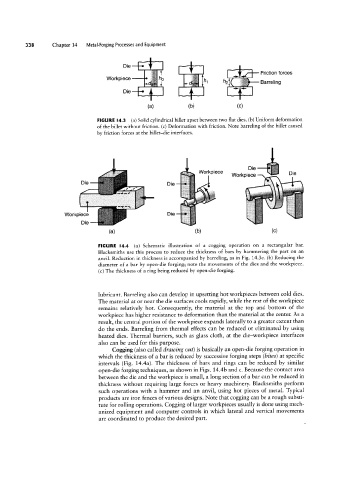

FIGURE l4.4 (a) Schematic illustration of a cogging operation on a rectangular bar.

Blacksmiths use this process to reduce the thickness of bars by hammering the part on an

anvil. Reduction in thickness is accompanied by barreling, as in Fig. 14.3c. (b) Reducing the

diameter of a bar by open-die forging; note the movements of the dies and the workpiece.

(c) The thickness of a ring being reduced by open-die forging.

lubricant. Barreling also can develop in upsetting hot Workpieces between cold dies.

The material at or near the die surfaces cools rapidly, while the rest of the workpiece

remains relatively hot. Consequently, the material at the top and bottom of the

workpiece has higher resistance to deformation than the material at the center. As a

result, the central portion of the workpiece expands laterally to a greater extent than

do the ends. Barreling from thermal effects can be reduced or eliminated by using

heated dies. Thermal barriers, such as glass cloth, at the die-workpiece interfaces

also can be used for this purpose.

Cogging (also called drawing out) is basically an open-die forging operation in

which the thickness of a bar is reduced by successive forging steps (bites) at specific

intervals (Fig. 14.4a). The thickness of bars and rings can be reduced by similar

open-die forging techniques, as shown in Figs. 14.4b and c. Because the contact area

between the die and the workpiece is small, a long section of a bar can be reduced in

thickness without requiring large forces or heavy machinery. Blacksmiths perform

such operations with a hammer and an anvil, using hot pieces of metal. Typical

products are iron fences of various designs. Note that cogging can be a rough substi-

tute for rolling operations. Cogging of larger Workpieces usually is done using mech-

anized equipment and computer controls in which lateral and vertical movements

are coordinated to produce the desired part.