Page 360 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 360

F

340 Chapter 14 Metal-Forging Processes and Equipment

Die

Die

(8) (D) (C)

External and internal draft angles

Flash Flib Web Gutter

Parting line

Ci;?:;r

Land Parting

line

Tram une

ld)

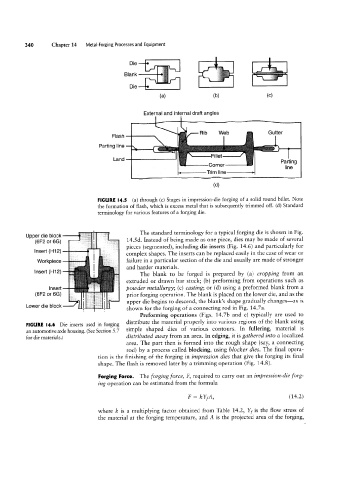

FIGURE I4.5 (a) through (c) Stages in impression-die forging of a solid round billet. Note

the formation of flash, which is excess metal that is subsequently trimmed off. (d) Standard

terminology for various features of a forging die.

The standard terminology for a typical forging die is shown in Fig.

Upper die block

(6F2 or 6(5) 14.5d. Instead of being made as one piece, dies may be made of several

pieces (segmented), including die inserts (Fig. 14.6) and particularly for

Insert (H12)

complex shapes. The inserts can be replaced easily in the case of wear or

Workpiece failure in a particular section of the die and usually are made of stronger

and harder materials.

Insert (H1 2)

The blank to be forged is prepared by (a) cropping from an

extruded or dravvn bar stock; (b) preforming from operations such as

Insert powder metallurgy; (c) casting; or (d) using a preformed blank from a

(6F2 or 6G) prior forging operation. The blank is placed on the lower die, and as the

upper die begins to descend, the blank’s shape gradually changes-as is

Lower die block

shown for the forging of a connecting rod in Fig. 14.7a.

Preforming operations (Figs. 14.7b and c) typically are used to

distribute the material properly into various regions of the blank using

FIGURE l4.6 Die inserts used in forging

an automotive axle housing. (See Section 5.7 simple shaped dies of various contours. In fullering, material is

for die materials.) distributed au/ay from an area. In edging, it is gathered into a localized

area. The part then is formed into the rough shape (say, a connecting

rod) by a process called blocking, using blocker dies. The final opera-

tion is the finishing of the forging in impression dies that give the forging its final

shape. The flash is removed later by a trimming operation (Fig. 14.8).

Forging Force. The forging force, F, required to carry out an impression-die forg-

ing operation can be estimated from the formula

F = leYfA, (14.2)

where le is a multiplying factor obtained from Table 14.2, Yf is the flow stress of

the material at the forging temperature, and A is the projected area of the forging,