Page 364 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 364

344 Chapter 14 Metal-Forging Processes and Equipment

|<-147 mm->|

Kickout pin Die T3§""“

Bm

"

P“"°"

1- im.,

3-

.. ., ,,;,; ;};;,_ ,;; vu

l|l

.ir in die

'ss'

)<-114 mm->|T

4.

(H) (D)

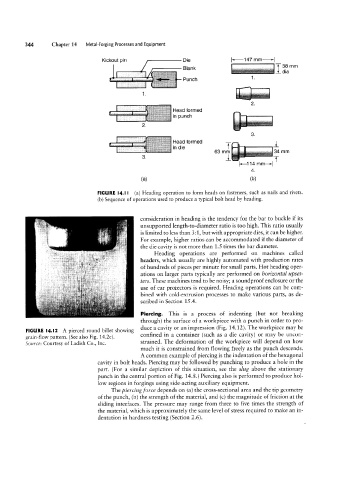

FIGURE |4.l| (a) Heading operation to form heads on fasteners, such as nails and rivets.

(b) Sequence of operations used to produce a typical bolt head by heading.

consideration in heading is the tendency for the bar to buckle if its

unsupported length-to-diameter ratio is too high. This ratio usually

is limited to less than 3:1, but with appropriate dies, it can be higher.

For example, higher ratios can be accommodated if the diameter of

the die cavity is not more than 1.5 times the bar diameter.

Heading operations are performed on machines called

headers, which usually are highly automated with production rates

of hundreds of pieces per minute for small parts. Hot heading oper-

ations on larger parts typically are performed on horizontal upset-

ters. These machines tend to be noisy; a soundproof enclosure or the

use of ear protectors is required. Heading operations can be com-

bined with cold-extrusion processes to make various parts, as de-

scribed in Section 15.4.

Piercing. This is a process of indenting (but not breaking

through) the surface of a workpiece with a punch in order to pro-

FIGURE |4.l2 A pierced round billet showing duce a cavity or an impression (Fig. 14.12). The workpiece may be

grain-flow pattern. (See also Fig. 14.2c). confined in a container (such as a die cavity) or may be uncon-

Source: Courtesy of Ladish Co., Inc. strained. The deformation of the workpiece will depend on how

much it is constrained from flowing freely as the punch descends.

A common example of piercing is the indentation of the hexagonal

cavity in bolt heads. Piercing may be followed by punching to produce a hole in the

part. (For a similar depiction of this situation, see the slug above the stationary

punch in the central portion of Fig. 14.8.) Piercing also is performed to produce hol-

low regions in forgings using side-acting auxiliary equipment,

The piercing force depends on (a) the cross-sectional area and the tip geometry

of the punch, (b) the strength of the material, and (c) the magnitude of friction at the

sliding interfaces. The pressure may range from three to five times the strength of

the material, which is approximately the same level of stress required to make an in-

dentation in hardness testing (Section 2.6).