Page 367 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 367

Mandrel

rouers

9 7-5

Planetary

me

Retainer Driven Cam

Hammer Workpiece

Die rV'r Q:

4 .QM Q m

(H) (D) r',~rr

“‘ QR Par i

Backer 'Q Workpiece

.eta %

, .s.:z M

'”

2

..

*

1.

5:5

W

\/\/edge Die Qs; Ejector _A,,, ll

~.

!%=i!i~§

‘Lv

lx

W.

Open Swaging Ejecting

position position position

1 2. 3.

(C) (d)

il

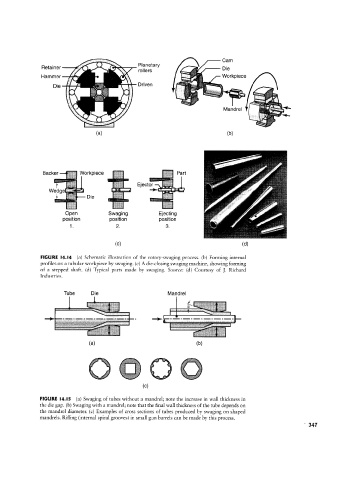

FIGURE l4.l4 (a) Schematic illustration of the rotary-svvaging process. (b) Forming internal

profiles on a tubular workpiece by swaging. (c) A die-closing swaging machine, showing forming

of a stepped shaft. (d) Typical parts made by swaging. Source: (d) Courtesy of ]. Richard

Industries.

;

Tube Die ""»* . Mandrel Ili: mx’

l

ii "

(H) *" (D)

....

:

§ §. -? § -f< '<f~; " - E § ss ‘§§ ‘- as

~§

i

(C)

FIGURE l4.I5 (a) Swaging of tubes without a mandrel; note the increase in wall thickness in

the die gap. (b) Swaging with a mandrel; note that the final wall thickness ofthe tube depends on

the mandrel diameter (c) Examples of cross sections of tubes produced by swaging on shaped

mandrels. Rifling (internal spiral grooves) in small gun barrels can be made by this process.