Page 368 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 368

8 Chapter 14 Metal-Forging Processes and Equipment

|4.5 Forgeability of Metals; Forging Defects

Porgeability is generally defined as the capability of a material to undergo deforma-

tion without cracking. Various tests have been developed to quantify forgeability;

however, because of their complex nature, only two simple tests have had general

acceptance: upsetting and hot twist.

In the upsetting test, a solid, cylindrical specimen is upset between flat dies,

and the reduction in height at which cracking on the barreled surfaces begins is

noted (see also Fig. 2.20d). The greater the deformation prior to cracking, the

greater the forgeability of the metal. The second method is the hot-twist test, in

which a round specimen is twisted continuously in the same direction until it fails.

This test is performed on a number of specimens and at different temperatures, and

the number of complete turns that each specimen undergoes before failure at each

temperature is plotted. The temperature at which the maximum number of turns oc-

curs then becomes the forging temperature for maximum forgeability. The hot-twist

test has been found to be useful particularly for steels.

The forgeability of various metals and alloys is given in Table 14.3 in decreas-

ing order. Forgeability is based on considerations such as ductility and strength of

the material, forging temperature required, frictional behavior, and the quality of

the forgings produced. These ratings should be regarded only as general guidelines.

Typical hot-forging temperature ranges for various metals and alloys are included in

Table 14.3. Note that higher forging temperature does not necessarily indicate

greater difficulty in forging that material. For warm forging, temperatures range

from 200° to 300°C for aluminum alloys and from 550° to 750°C for steels.

Forging Defects. In addition to surface cracking, other defects can develop dur-

ing forging as a result of the material flow pattern in the die, as described next in

Section 14.6 regarding die design. For example, if there is an insufficient volume of

material to fill the die cavity completely, the web may buckle during forging and

develop laps (Fig. 14.16a). On the other hand, if the web is too thick, the excess

material flows past the already formed portions of the forging and develops inter-

nal cracks (Fig. 14.16b).

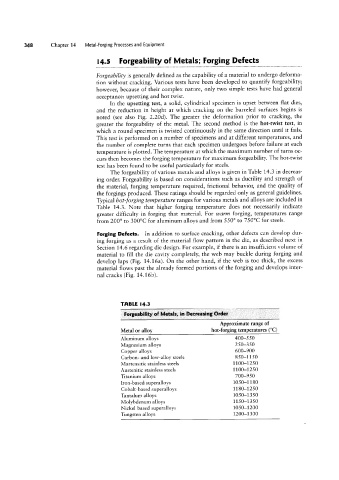

TABLE l4.3

forgeability uf Metals, in Decreasing Order

Approximate range of

Metal or alloy hot-forging temperatures ( C)

Aluminum alloys 400-550

Magnesium alloys 250-350

Copper alloys 600-900

Carbon- and low-alloy steels 850-1150

Martensitic stainless steels 1100-1250

Austenitic stainless steels 1100-1250

Titanium alloys 700-950

Iron-based superalloys 1050-1180

Cobalt-based superalloys 1 180-1250

Tantalum alloys 1050-1350

Molybdenum alloys 1 150-1350

Nickel-based superalloys 1050-1200

Tungsten alloys 1200-1300