Page 373 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 373

Section 14.8 Forging Machines

A common cause of failure in cold-extrusion dies is that of the operator (or of a

programmable robot) to fail to remove a formed part from the die before loading it

with another blank.

|4.8 Forging Machines

A variety of forging machines is available with a range of capacities (tonnage),

speeds, and speed-stroke characteristics (Table 14.4).

Hydraulic Presses. These presses operate at constant speeds and are load

limited, or load restricted. In other words, a press stops if the load required ex-

ceeds its capacity. Large amounts of energy can be transmitted to a workpiece by

a constant load throughout a stroke-the speed of which can be controlled.

Because forging in a hydraulic press takes longer than in the other types of forging

machines described next, the workpiece may cool rapidly unless the dies are heated

(see isothermal forging, Section 14.4). Compared with mechanical presses, hy-

draulic presses are slower and involve higher initial costs, but they require less

maintenance.

A hydraulic press typically consists of a frame with two or four columns, pis-

tons, cylinders (Fig. 14.17), rams, and hydraulic pumps driven by electric motors.

The ram speed can be varied during the stroke. Press capacities range up to 125 MN

for open-die forging and up to 450 MN in North America, 640 MN in France, and

730 MN in Russia for closed-die forging. The main landing-gear support beam for

the Boeing 747 aircraft is forged in a 450-MN hydraulic press, shown in Fig. 14.1c

TABLE l4.4

Typical Speed Ranges,of Forging Equipment

Equipment m/s

Hydraulic press 0.06-0.30

Mechanical press 0.06-1.5

Screw press 0.6-1.2

Gravity drop hammer 3.6-4.8

Power drop hammer 3.0-9.0

4.5-9.0

Counterblow hammer If

egg e Flywheel § Fluid

Friction

drive

1

Screw

Ram Ram Ram

Crank Knuckle-joint Screw Hydraulic

(H) (D) (C) (d)

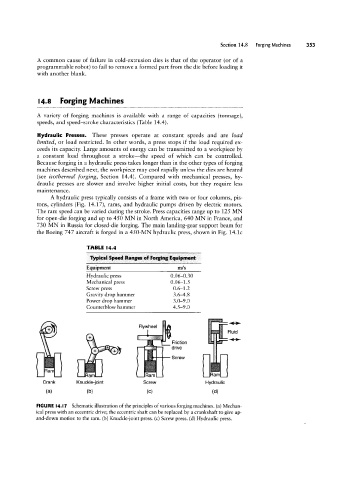

FIGURE |4.l1 Schematic illustration of the principles of various forging machines. (a) Mechan-

ical press with an eccentric drive; the eccentric shaft can be replaced by a crankshaft to give up-

and-down motion to the ram. (b) Knuckle-joint press. (c) Screw press. (d) Hydraulic press.