Page 377 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 377

Summary 357

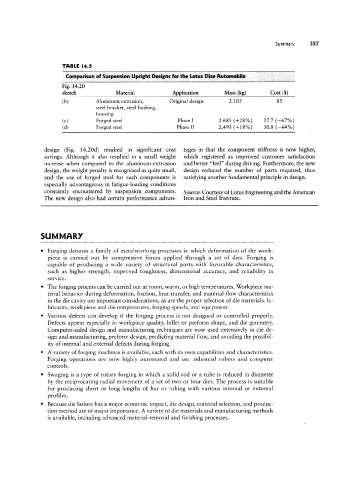

TABLE l4.5

Comparison of Suspension Upright Designs for the Lotus Elise Automobile

Fig. 14.20

sketch Material Application Mass (kg) Cost ($)

(b) Aluminum extrusion, Original design 2.105 85

steel bracket, steel bushing,

housing

(c) Forged steel Phase I 2.685 (+28%) 27.7 (-67%)

(d) Forged steel Phase II 2.493 (+18%) 30.8 (-64%)

design (Fig. 14.20d) resulted in significant cost tages in that the component stiffness is now higher,

savings. Although it also resulted in a small weight which registered as improved customer satisfaction

increase when compared to the aluminum-extrusion and better “feel” during driving. Furthermore, the new

design, the weight penalty is recognized as quite small, design reduced the number of parts required, thus

and the use of forged steel for such components is satisfying another fundamental principle in design.

especially advantageous in fatigue-loading conditions

constantly encountered by suspension components. Source: Courtesy of Louis Engineering and the American

The new design also had certain performance advan- Iron and Steel Institute.

SUMMARY

° Forging denotes a family of metalworking processes in which deformation of the work-

piece is carried out by compressive forces applied through a set of dies. Forging is

capable of producing a wide variety of structural parts with favorable characteristics,

such as higher strength, improved toughness, dimensional accuracy, and reliability in

service.

° The forging process can be carried out at room, warm, or high temperatures. Workpiece ma-

terial behavior during deformation, friction, heat transfer, and material-flow characteristics

in the die cavity are important considerations, as are the proper selection of die materials, lu-

bricants, workpiece and die temperatures, forging speeds, and equipment.

° Various defects can develop if the forging process is not designed or controlled properly.

Defects appear especially in workpiece quality, billet or preform shape, and die geometry.

Computer-aided design and manufacturing techniques are now used extensively in die de-

sign and manufacturing, preform design, predicting material flow, and avoiding the possibil-

ity of internal and external defects during forging.

° A variety of forging machines is available, each with its own capabilities and characteristics.

Forging operations are now highly automated and use industrial robots and computer

controls.

° Swaging is a type of rotary forging in which a solid rod or a tube is reduced in diameter

by the reciprocating radial movement of a set of two or four dies. The process is suitable

for producing short or long lengths of bar or tubing with various internal or external

profiles.

° Because die failure has a major economic impact, die design, material selection, and produc-

tion method are of major importance. A variety of die materials and manufacturing methods

is available, including advanced material-removal and finishing processes.