Page 381 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 381

Containerlin

Section 15.1

Introduction

Typical products made by extrusion are

because the material is under high triaxial com- DI Container 36|

g

pression. Since the die geometry remains un- ,,=~;~

,

changed throughout the operation, extruded e > '€ ‘ H W ,pdf pyyy;y_L ,,,,,,;;;; Pressing stem

yyh,

.//

products typically have a constant cross section. *7

Die backer n n 1, ,rvi 5

railings for sliding doors, Window frames, tubing 5 ,Sf fee ;&-P’ ww,

auf’

having Various cross sections, aluminum ladder _ » "'" ,M / My /

frames, and numerous structural and architec-

tural shapes. Extrusions can be cut into desired :=E2§??=22=fff1".'

lengths, which then become discrete parts, such Extrusion Dummy block

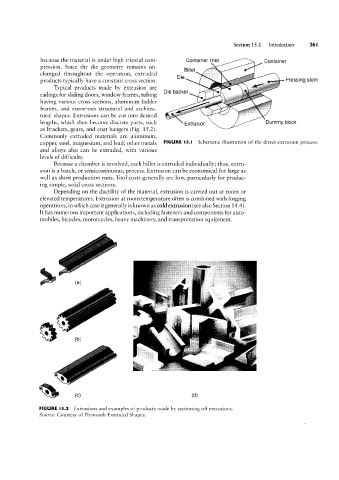

as brackets, gears, and coat hangers (Fig. 152).

Commonly extruded materials are aluminum,

copper, steel, magnesium, and lead; other metals FIGURE I5.l Schematic illustration of the direct-extrusion process

and alloys also can be extruded, with various

levels of difficulty.

Because a chamber is involved, each billet is extruded individually; thus, extru-

sion is a batch, or semicontinuous, process. Extrusion can be economical for large as

Well as short production runs. Tool costs generally are low, particularly for produc-

ing simple, solid cross sections.

Depending on the ductility of the material, extrusion is carried out at room or

elevated temperatures. Extrusion at room temperature often is combined with forging

operations, in which case it generally is known as cold extrusion (see also Section 14.4).

It has numerous important applications, including fasteners and components for auto-

mobiles, bicycles, motorcycles, heavy machinery, and transportation equipment.

(C) (Oi)

FIGURE l5.2 Extrusions and examples of products made by sectioning off extrusions.

Source: Courtesy of Plymouth Extruded Shapes.