Page 386 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 386

Chapter 15 Metal Extrusion and Drawing Processes and Equipment

Mandrel Cgntainer Mandrel Die Container

Tube

Ram

Tube D'e

Ram

Spider

Billet

Billet 3p|der Mandrel

(H) (D)

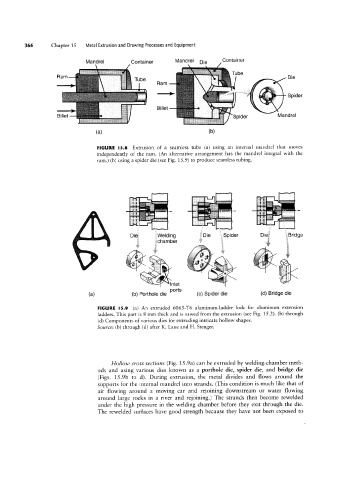

FIGURE l5.8 Extrusion of a seamless tube (a) using an internal mandrel that moves

independently of the ram. (An alternative arrangement has the mandrel integral with the

ram.) (b) using a spider die (see Fig. 15.9) to produce seamless tubing.

1»f .

~

llrrr

"i "i;i‘;‘! "" ' sw

¢= f" f 1€»ff f¢f~ '

2: .,,. Ji''mi "iil _

Egwelding sy €5;Spider r s

éichamber “ E§;Bridge

~ tv

lnlet \ 2

”

ports

(b) Porthole die (c) Spider die (d) Bridge die

FIGURE l5.9 (a) An extruded 6063-T6 aluminum-ladder lock for aluminum extension

ladders. This part is 8 mm thick and is sawed from the extrusion (see Fig. 152). lb) through

(d) Components of various dies for extruding intricate hollow shapes.

Source: (b) through (d) after K. Laue and H. Stenger.

Hollow cross sections (Fig. 15.9a) can be extruded by welding-chamber meth-

ods and using various dies known as a porthole die, spider die, and bridge die

(Figs. 15.9b to d). During extrusion, the metal divides and flows around the

supports for the internal mandrel into strands. (This condition is much like that of

air flowing around a moving car and rejoining downstream or water flowing

around large rocks in a river and rejoining.) The strands then become rewelded

under the high pressure in the Welding chamber before they exit through the die.

The rewelded surfaces have good strength because they have not been exposed to