Page 390 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 390

370 Chapter 15 Metal Extrusion and Drawing Processes and Equipment

Investigating material flow during the defor- then polished and etched to display the grain flow,

mation of the slug helps avoid defects and leads to as shown in Fig. 15.14 (see also Fig. 14.11).

improvements in punch and die design. Furthermore,

the part usually is sectioned in the midplane and

FIGURE l5.I3 Production steps for a cold-extruded FIGURE l5.l4 A cross section of the metal part in

spark plug. Source: Courtesy of National Machinery Fig. 15 .13, showing the grain-flow pattern. Source:

Company. Courtesy of National Machinery Company.

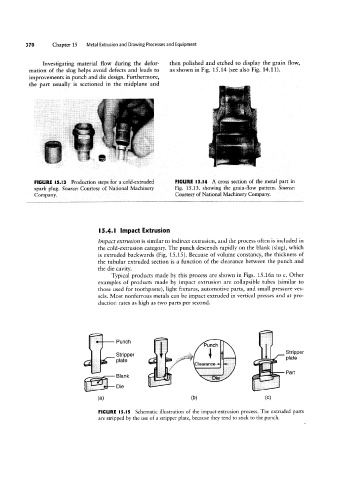

l5.4.l Impact Extrusion

Impact extrusion is similar to indirect extrusion, and the process often is included in

the cold-extrusion category. The punch descends rapidly on the blank (slug), which

is extruded backwards (Fig. 15.15 ). Because of volume constancy, the thickness of

the tubular extruded section is a function of the clearance between the punch and

the die cavity.

Typical products made by this process are shown in Figs. 15.16a to c. Other

examples of products made by impact extrusion are collapsible tubes (similar to

those used for toothpaste), light fixtures, automotive parts, and small pressure ves-

sels. Most nonferrous metals can be impact extruded in vertical presses and at pro-

duction rates as high as two parts per second.

¢ '- . Slgléper

.

ii.'

2

=

s

Punch

PU"'Ch

J,

Stripper

;§_

.

plate

M Hank Clearance ‘

Die ,»ir Ei ""t““t"‘

(H) (D) (C)

FIGURE l5.I5 Schematic illustration of the impact-extrusion process. The extruded parts

are stripped by the use of a stripper plate, because they tend to stick to the punch.