Page 391 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 391

Workpiece Section 15 5 Extrusion Defects

Before After

Blank

l

Punch

i 'i

l

Knockout -_Ti

, (ejector)

(61) (b) (C)

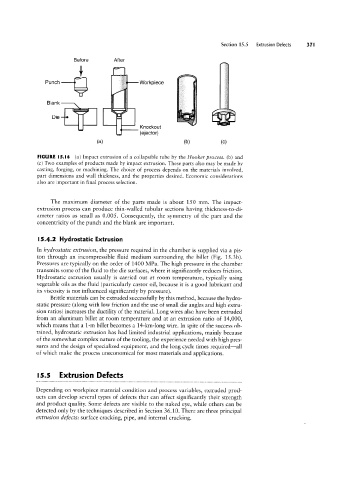

FIGURE l5.I6 (a) Impact extrusion of a collapsible tube by the Hooker process. (b) and

(c) Tvvo examples of products made by impact extrusion. These parts also may be made by

casting, forging, or machining. The choice of process depends on the materials involved,

part dimensions and Wall thickness, and the properties desired. Economic considerations

also are important in final process selection.

The maximum diameter of the parts made is about 150 mm. The impact-

extrusion process can produce thin-walled tubular sections having thickness-to-di-

ameter ratios as small as 0.005. Consequently, the symmetry of the part and the

concentricity of the punch and the blank are important.

l5.4.2 Hydrostatic Extrusion

In hydrostatic extrusion, the pressure required in the chamber is supplied via a pis-

ton through an incompressible fluid medium surrounding the billet (Fig. 15.3b).

Pressures are typically on the order of 1400 MPa. The high pressure in the chamber

transmits some of the fluid to the die surfaces, Where it significantly reduces friction.

Hydrostatic extrusion usually is carried out at room temperature, typically using

vegetable oils as the fluid (particularly castor oil, because it is a good lubricant and

its viscosity is not influenced significantly by pressure).

Brittle materials can be extruded successfully by this method, because the hydro-

static pressure (along with lovv friction and the use of small die angles and high extru-

sion ratios) increases the ductility of the material. Long wires also have been extruded

from an aluminum billet at room temperature and at an extrusion ratio of 14,00(),

which means that a 1-m billet becomes a 14-km-long Wire. ln spite of the success ob-

tained, hydrostatic extrusion has had limited industrial applications, mainly because

of the somewhat complex nature of the tooling, the experience needed with high pres-

sures and the design of specialized equipment, and the long cycle times required-all

of which make the process uneconomical for most materials and applications.

l5.5 Extrusion Defects

Depending on workpiece material condition and process variables, extruded prod-

ucts can develop several types of defects that can affect significantly their strength

and product quality. Some defects are visible to the naked eye, While others can be

detected only by the techniques described in Section 36.10. There are three principal

extrusion defects: surface cracking, pipe, and internal cracking.