Page 375 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 375

Section 14.9 Economics of Forging 355

14.9 Economics of Forging

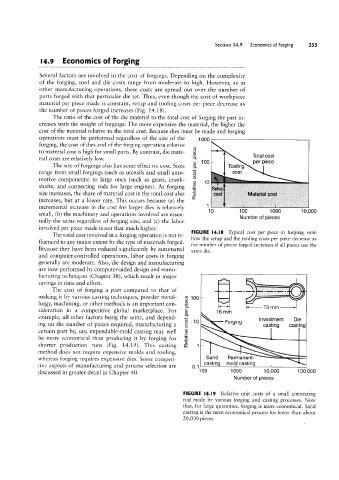

Several factors are involved in the cost of forgings. Depending on the complexity

of the forging, tool and die costs range from moderate to high. However, as in

other manufacturing operations, these costs are spread out over the number of

parts forged with that particular die set. Thus, even though the cost of workpiece

material per piece made is constant, setup and tooling costs per piece decrease as

the number of pieces forged increases (Fig. 14.18).

The ratio of the cost of the die material to the total cost of forging the part in-

creases with the weight of forgings: The more expensive the material, the higher the

cost of the material relative to the total cost. Because dies must be made and forging

operations must be performed regardless of the size of the g `

1 000

forging, the cost of dies and of the forging operation relative

to material cost is high for small parts. By contrast, die mate-

-Q Total cost

rial costs are relatively low. 100 per iece

=-

The size of forgings also has some effect on cost. Sizes Q) Tooling p

2.

range from small forgings (such as utensils and small auto- 15 cost

O

motive components) to large ones (such as gears, crank- .a... -;.;_;. .___ _ _

shafts, and connecting rods for large engines). As forging .2

5 Setup _

size increases, the share of material cost in the total cost also g ces! Matenai cost

increases, but at a lower rate. This occurs because (a) the 1 i 't

incremental increase in die cost for larger dies is relatively

10 100 1000 10,000

small, (b) the machinery and operations involved are essen-

Number of pieces

tially the same regardless of forging size, and (c) the labor

involved per piece made is not that much higher.

FIGURE |4.l8 Typical cost per piece in forging; note

The total cost involved in a forging operation is not in-

how the setup and the tooling costs per piece decrease as

fluenced to any major extent by the type of materials forged.

the number of pieces forged increases if all pieces use the

Because they have been reduced significantly by automated

same die.

and computer-controlled operations, labor costs in forging

generally are moderate. Also, die design and manufacturing

are now performed by computer-aided design and manu-

facturing techniques (Chapter 38), which result in major

savings in time and effort.

The cost of forging a part compared to that of 100 - >

making it by various casting techniques, powder metal-

lurgy, machining, or other methods is an important con-

l*-*i F173 mm

sideration in a competitive global marketplace. For 16 mm

example, all other factors being the same, and depend- Investment Die

ing on the number of pieces required, manufacturing a 10 Forgmg casting casting

certain part by, say, expendable-mold casting may well

be more economical than producing it by forging for

shorter production runs (Fig. 14.19). This casting -|_

method does not require expensive molds and tooling,

whereas forging requires expensive dies. Some competi- Sand Permanent-

tive aspects of manufacturing and process selection are 0.1 casting mold casting

discussed in greater detail in Chapter 40. 100 1000 10,000 100,000

Number of pieces

FIGURE l4.l9 Relative unit costs of a small connecting

rod made by various forging and casting processes. Note

that, for large quantities, forging is more economical. Sand

casting is the most economical process for fewer than about

20,000 pieces.