Page 404 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 404

<-' `i ;

D

38 Chapter 16 Sheet-Metal Forming Processes and Equipment

, P

F

A r

Die . ____ , A C _L i Fracture

Surface

Penetration

f¢ »;ii; .it , l1

Sheet T Slug

Ca B lai k"

->l i+C|earance

(H)

$ dimension

Penetration depth Burnish

Rollover depth _

Burnish depth

_ i

Sheet

(D

5 5 thickness

"“' £1

§ Q l, Fracture

angle

'-L Burr height i<-dimension

‘d

Breakout

(D)

>~"§i§<?§"

Fiattened portion

Burr

under the punch

A

Q

BUVV h9'Qht1i‘ Dishing C Smooth surface

L E Rough surface

ea s ug 5-»-- C (burnished)

(C)

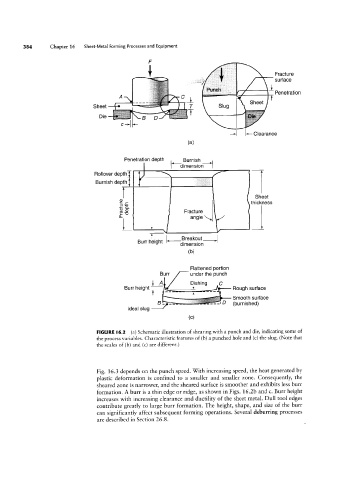

FIGURE |6.2 (a) Schematic illustration of shearing With a punch and die, indicating some of

the process variables. Characteristic features of (b) a punched hole and (c) the slug. (Note that

the scales of (b) and (c) are different.)

Fig. 16.3 depends on the punch speed. With increasing speed, the heat generated by

plastic deformation is confined to a smaller and smaller zone. Consequently, the

sheared zone is narrower, and the sheared surface is smoother and exhibits less burr

formation. A burr is a thin edge or ridge, as shown in Figs. 16.2b and c. Burr height

increases with increasing clearance and ductility of the sheet metal. Dull tool edges

contribute greatly to large burr formation. The height, shape, and size of the burr

can significantly affect subsequent forming operations. Several deburring processes

are described in Section 26.8.