Page 407 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 407

Section 16.2 Shearing

(H)

Blanking punch

Upper

Upper pressure pad pressure

pad

Stinger (irnpingement ring)

Sheet metal

Fracture

,l,_

Blanking die surface

Lower pressure cushion

Lower

Support pressure

cushion

rr" l tttte

Clearance

(D)

t t

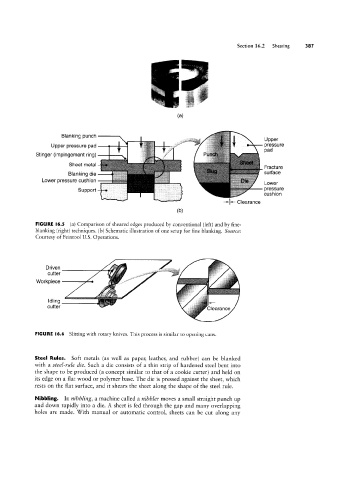

FIGURE l6.5 (a) Comparison of sheared edges produced by conventional (left) and by fine-

blanking (right) techniques. (b) Schematic illustration of one setup for fine blanking. S01/r1'ce~

cutter

Courtesy of Feintool U.S. Operations.

yyzz

y,

Drive I1 yut .at ,egg

Work iece

p f

'd""9 ,

cutter

FIGURE l6.6 Slitting with rotary knives. This process is similar to opening cans.

Steel Rules. Soft metals (as Well as paper, leather, and rubber) can be blanked

with a steel-rule die. Such a die consists of a thin strip of hardened steel bent into

the shape to be produced (a concept similar to that of a cookie cutter) and held on

its edge on a flat wood or polymer base. The die is pressed against the sheet, which

rests on the flat surface, and it shears the sheet along the shape of the steel rule.

Nibbling. In nibbling, a machine called a nibbler moves a small straight punch up

and down rapidly into a die. A sheet is fed through the gap and many overlapping

holes are made. With manual or automatic control, sheets can be cut along any