Page 405 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 405

::::::==\===§E::: 3 8 Section 16.2 Shearing

Q

3 8

o

>

I

<|'

O

1-

‘_

C0

<_\|

ll

2=a2aaa§zzzz;zzef*l- |

| |ll. |lll| "“" ff 3 (\| S

.=======:=---I :Ii--::~

if

<======:»E::::a

e¢:===-=

~=======:M=====¥

====:==5=EE!EE

:::::::=’==E:::::

Illlll'

lllllllff' »lll||

‘|l""|' num ,|:=:I!I¢§" -=====EE¢%¢z§====l O

N

"

4

1 1|

"““" =“““’ 1

|==EE=¢"'“"'

C, ”‘ "” S3 O O O § 3 391

earance, c

__

1. 2. 3. 9 2 3

(3) (D)

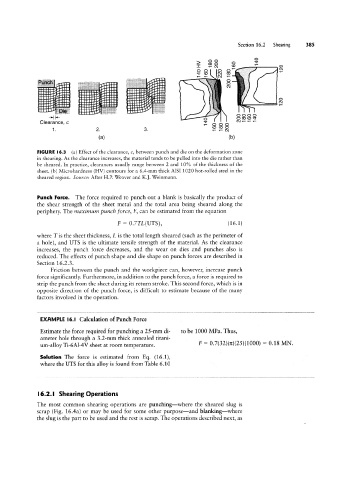

FIGURE l6.3 (a) Effect of the clearance, c, between punch and die on the deformation zone

in shearing. As the clearance increases, the material tends to be pulled into the die rather than

be sheared. In practice, clearances usually range between 2 and 10% of the thickness of the

sheet. (b) Microhardness (HV) contours for a 6.4-mm thick AISI 1020 hot-rolled steel in the

sheared region. Source: After H.P. Weaver and K.]. Weinmann.

Punch Force. The force required to punch out a blank is basically the product of

the shear strength of the sheet metal and the total area being sheared along the

periphery. The maximum punch force, F, can be estimated from the equation

F = o.7TL(UTs), (16.1)

where T is the sheet thickness, L is the total length sheared (such as the perimeter of

a hole), and UTS is the ultimate tensile strength of the material. As the clearance

increases, the punch force decreases, and the wear on dies and punches also is

reduced. The effects of punch shape and die shape on punch forces are described in

Section 16.23.

Friction between the punch and the workpiece can, however, increase punch

force significantly. Furthermore, in addition to the punch force, a force is required to

strip the punch from the sheet during its return stroke. This second force, which is in

opposite direction of the punch force, is difficult to estimate because of the many

factors involved in the operation.

EXAMPLE l6.l Calculation of Punch Force

Estimate the force required for punching a 25-mm di- to be 1000 MPa. Thus,

ameter hole through a 3.2-mm thick annealed titani-

um-alloy Ti-6Al-4V sheet at room temperature. F : 0~7l32)l75l(25)(1000) 0 18 MN

Solution The force is estimated from Eq. (16.1),

where the UTS for this alloy is found from Table 6.10

l6.2.l Shearing Operations

The most common shearing operations are punching-where the sheared slug is

scrap (Fig. 16.4a) or may be used for some other purpose-and blanking-where

the slug is the part to be used and the rest is scrap. The operations described next, as