Page 410 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 410

390 Chapter 16 Sheet-Metal Forming Processes and Equipment

Sheet Sheared Clearance. Because the formability of the sheared part can be influenced by the

l6.2.3 Characteristics and Type of Shearing Dies

Shaving

quality of its sheared edges, clearance control is important. The appropriate clearance

Shearing edge depends on

° The type of material and its temper

° The thickness and size of the blank

(H)

° Its proximity to the edges of other sheared edges or the edges of the original

blank.

Die they may be as small as 1% (as in fine blanking) or as large as 30%. The smaller

Clearances generally range between 2 and 8% of the sheet thickness, but

the clearance, the better is the quality of the edge. If the sheared edge is rough

Clearance

and not acceptable, it can be subjected to a process called shaving (Fig. 16.9a),

whereby the extra material from the edge is trimmed by cutting, as also depicted

(bl

in Fig. 21.3.

As a general guideline, la) clearances for soft materials are less than those for

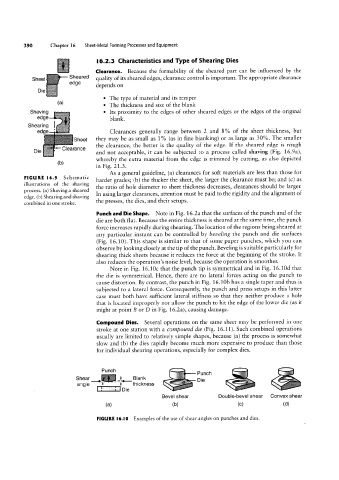

FIGURE l6.9 Schematic harder grades; (b) the thicker the sheet, the larger the clearance must be; and (c) as

illustrations of the shaving the ratio of hole diameter to sheet thickness decreases, clearances should be larger.

process. (a) Shaving a sheared In using larger clearances, attention must be paid to the rigidity and the alignment of

edge. (b) Shearing and shaving

combined in one stroke. the presses, the dies, and their setups.

Punch and Die Shape. Note in Fig. 16.2a that the surfaces of the punch and of the

die are both flat. Because the entire thickness is sheared at the same time, the punch

force increases rapidly during shearing. The location of the regions being sheared at

any particular instant can be controlled by bei/eling the punch and die surfaces

(Fig. 16.10). This shape is similar to that of some paper punches, which you can

observe by looking closely at the tip of the punch. Beveling is suitable particularly for

shearing thick sheets because it reduces the force at the beginning of the stroke. It

also reduces the operation’s noise level, because the operation is smoother.

Note in Fig. 16.10c that the punch tip is symmetrical and in Fig. 16.1Od that

the die is symmetrical. Hence, there are no lateral forces acting on the punch to

cause distortion. By contrast, the punch in Fig. 16.10b has a single taper and thus is

subjected to a lateral force. Consequently, the punch and press setups in this latter

case must both have sufficient lateral stiffness so that they neither produce a hole

that is located improperly nor allow the punch to hit the edge of the lower die (as it

might at point B or D in Fig. 16.2a), causing damage.

thickness

"4

Compound Dies. Several operations on the same sheet may be performed in one

stroke at one station with a compound die (Fig. 16.11). Such combined operations

usually are limited to relatively simple shapes, because (a) the process is somewhat

slow and (b) the dies rapidly become much more expensive to produce than those

for individual shearing operations, especially for complex dies.

shear__ _l__ Blank ,, Punch \ gvyw

Die

angle T ....

Die '~.a .. . in

Bevel shear Double-bevel shear Convex shear

la) (D) (C) (Ci)

FIGURE I6.I0 Examples of the use of shear angles on punches and dies.