Page 453 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 453

Bibliography 433

Because of the relatively thin materials used, springback, buckling, and wrinkling

are significant problems in sheet forming. Springback is a function of the yield

stress, the elastic modulus, and the ratio of bend radius to thickness. These prob-

lems can be reduced or eliminated by proper tool and die design, by minimizing

the unsupported length of the sheet during processing, and by controlling the

thickness of the incoming sheet and its mechanical properties.

Among important developments is the superplastic forming of diffusion-bonded

sheets. The process is capable of producing complex sheet-metal structures, par-

ticularly for aerospace applications (which require particularly high stiffness-to-

weight ratios).

Several test methods have been developed for predicting the formability of sheet

metals. In bending operations, the tensile reduction of the area of the sheet gives

an indication of its bendability (minimum bend radius); this also applies to, the

spinnability parameter of metals (maximum reduction in thickness per pass).

For general stamping operations, forming-limit diagrams are very useful, because

they establish quantitative relationships among the major and minor principal

strains that limit safe forming. For deep-drawing operations, the important pa-

rameter is the normal or plastic anisotropy of the sheet (the ratio of width strain

to thickness strain in tensile testing).

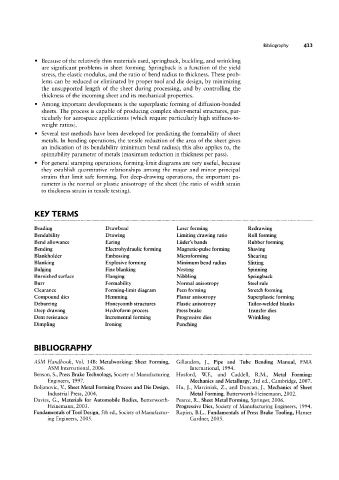

KEY TERMS

Beading Drawbead Laser forming Redrawing

Bendability Drawing Limiting drawing ratio Roll forming

Bend allowance Earing Liider’s bands Rubber forming

Bending Electrohydraulic forming Magnetic-pulse forming Shaving

Blankholder Embossing Microforming Shearing

Blanking Explosive forming Minimum bend radius Slitting

Bulging Fine blanking Nesting Spinning

Burnished surface Flanging Nibbling Springback

Burr Formability Normal anisotropy Steel rule

Clearance Forming-limit diagram Peen forming Stretch forming

Compound dies Hemming Planar anisotropy Superplastic forming

Deburring Honeycomb structures Plastic anisotropy Tailor-welded blanks

Deep drawing Hydroform process Press brake Transfer dies

Dent resistance Incremental forming Progressive dies Wrinkling

Dimpling Ironing Punching

BIBLIOGRAPHY

ASM Handbook, Vol. 14B: Metalworking: Sheet Forming, Gillanders, ]., Pipe and Tube Bending Manual, FMA

ASM International, 2006. International, 1994.

Benson, S., Press Brake Technology, Society of Manufacturing I-Iosford, WF., and Caddell, R.M., Metal Forming:

Engineers, 1997. Mechanics and Metallurgy, 3rd ed., Cambridge, 2007.

Boljanovic, V., Sheet Metal Forming Process and Die Design, Hu, ]., Marciniak, Z., and Duncan, ]., Mechanics of Sheet

Industrial Press, 2004. Metal Forming. Butterworth-Heinemann, 2002.

Davies, G., Materials for Automobile Bodies, Butterworth- Pearce, R., Sheet Metal Forming, Springer, 2006.

Heinemann, 2003. Progressive Dies, Society of Manufacturing Engineers, 1994.

Fundamentals of Tool Design, 5 th ed., Society of Manufactur- Rapien, B.L., Fundamentals of Press Brake Tooling, Hanser

ing Engineers, 2005. Gardner, 2005.