Page 451 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 451

Section 16.15 Economics of Sheet forming Operations

¢3*"'* "ii fl§l>

Basic C-frame Wide Adjustable Open-back Pillar Double

design design bed inclinable column

(H) (D) (C) (d) (9) (fl

‘Ely _

a‘§1§{lgg§§\~ § | ,§s,

= ‘*l§Q!;` Q,--:.‘..

® iii*

--#ses

ml!

! .

mf' i `1-.>

Hx

im'

,f

M”

lilnzu

lllq

lllb

QS Si ' Gi

ve

Is *ns !lQ`i§°L|r

1 -

me ==`W

3%

@. "`\¢:LPl °

'ill 15|

(9)

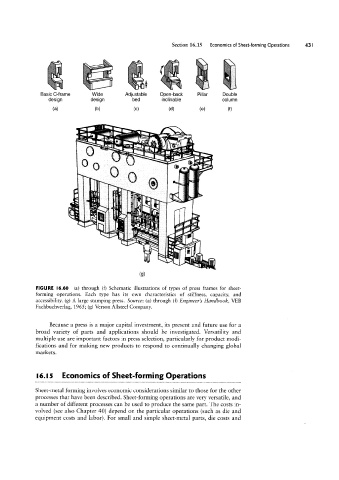

FIGURE |6.60 (a) through (f) Schematic illustrations of types of press frames for sheet-

forming operations. Each type has its own characteristics of stiffness, capacity, and

accessibility. (g) A large stamping press. Source: (a) through (f) Engineers Handbook, VEB

Fachbuchverlag, 1965; (g) Verson Allsteel Company.

Because a press is a major capital investment, its present and future use for a

broad variety of parts and applications should be investigated. Versatility and

multiple use are important factors in press selection, particularly for product modi-

fications and for making new products to respond to continually changing global

markets.

l6.l5 Economics of Sheet-forming Operations

Sheet-metal forming involves economic considerations similar to those for the other

processes that have been described. Sheet-forming operations are very versatile, and

a number of different processes can be used to produce the same part. The costs in-

volved (see also Chapter 40) depend on the particular operations (such as die and

equipment costs and labor), For small and simple sheet-metal parts, die costs and