Page 448 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 448

428 Chapter 16 Sheet-Metal Forming Processes and Equipment

l6.l3 Design Considerations in Sheet-metal Formmg

As with most other processes described throughout this book, certain design guide-

lines and practices have evolved with time. Careful design using the best established

design practices, computational tools, and manufacturing techniques is the best ap-

proach to achieving high-quality designs and realizing cost savings. The following

guidelines apply to sheet-metal-forming operations, with the most significant design

issues identified.

Blank Design. Material scrap is the primary concern in blanking operations. (See

also Table 40.6.) Poorly designed parts will not nest properly, and there can be con-

siderable scrap between successive blanking opera-

tions (Fig. 16.55). Some restrictions on blank shapes

are made by the design application, but whenever pos-

sible, blanks should be designed to reduce scrap to a

minimum.

Bending. In bending operations, the main concerns

are material fracture, wrinkling, and the inability to

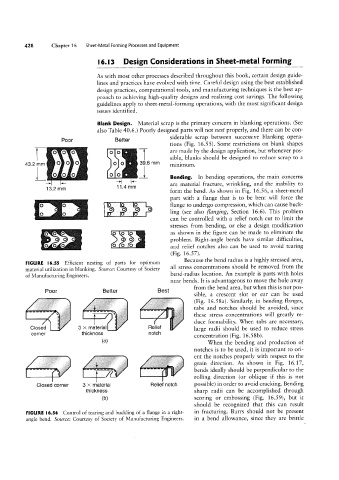

form the bend. As shown in Fig. 16.56, a sheet-metal

`73`

part with a flange that is to be bent will force the

flange to undergo compression, which can cause buck-

ling (see also Hanging, Section 16.6). This problem

can be controlled with a relief notch cut to limit the

stresses from bending, or else a design modification

as shown in the figure can be made to eliminate the

problem. Right-angle bends have similar difficulties,

and relief notches also can be used to avoid tearing

(Fig. 16.57>.

Because the bend radius is a highly stressed area,

FIGURE l6.55 Efficient nesting of parts for optimum

material utilization in blanking. Source: Courtesy of Society all stress concentrations should be removed from the

of Manufacturing Engineers. bend-radius location. An example is parts with holes

near bends. It is advantageous to move the hole away

from the bend area, but when this is not pos-

Better

Poor `.i.- Best sible, a crescent slot or ear can be used

' tabs and notches should be avoided, since

-`”i E; titr to (Fig. 16.58a). Similarly, in bending flanges,

._ `i~` | g eef , these stress concentrations will greatly re-

large radii should be used to reduce stress

Closed E' 3 X_ melellel Flellel duce formability. When tabs are necessary,

corner thickness (al notch concentration (Fig. 16.58b).

When the bending and production of

...FY

ent the notches properly with respect to the

notches is to be used, it is important to ori-

grain direction. As shown in Fig. 16.17,

bends ideally should be perpendicular to the

rolling direction (or oblique if this is not

C if

Closed corner 3 >< material Relief notch possible) in order to avoid cracking. Bending

thickness sharp radii can be accomplished through

(b) scoring or embossing (Fig. 16.59), but it

should be recognized that this can result

FIGURE l6.56 Control of tearing and buckling of a flange in a right» in fracturing. Burrs should not be present

angle bend. Source: Courtesy of Society of Manufacturing Engineers. in a bend allowance, since they are brittle