Page 449 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 449

-1 2

Section 16.13

Design Considerations in Sheet metal Forming

(b (C) §

a bend.

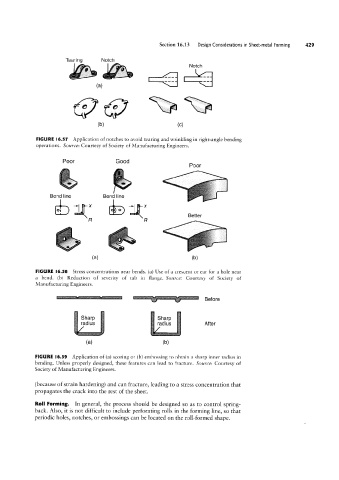

FIGURE l6.57 Application of notches to avoid tearing and Wrinkling in right-angle bending

operations. Source: Courtesy of Society of Manufacturing Engineers.

Poor Good

Poor

ux ur

Béllel'

(H) (bl

FIGURE l6.S8 Stress concentrations near bends. (a) Use ofa crescent or ear for a hole near

(b) Reduction of severity of tab in flange. Source: Courtesy of Society of

Manufacturing Engineers.

Bef O re

Sharp Sharp

radius radius After

(a) (D)

FIGURE |6.59 Application of (a) scoring or (b) embossing to obtain a sharp inner radius in

bending. Unless properly designed, these features can lead to fracture. Source: Courtesy of

Society of Manufacturing Engineers.

because of strain hardenin s and can fracture leadin to a stress concentration that

g

,

propagates the crack into the rest of the sheet.

Roll Forming. In general, the process should be designed so as to control spring-

back. Also, it is not difficult to include perforating rolls in the forming line, so that

periodic holes, notches, or embossings can be located on the roll-formed shape.