Page 447 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 447

,§

Section 16.12 Manufacturing of Metal Honeycomb Structures 2

, Corrugated

Adhesive

impregnated

Slice

block

Expanded Corrugated

sheet

RO" sheer mek Roll Corrugating Corrugated

rolls

panel Z'.“`”` pane'

(al (bl

gg Face sheet

Adhesive ~~ -s mzixgba ., . Expanded

honeycomb

scr|m_ cloth lll ;¢§§ |mi nmmgrlllllll Core

(optional)

WE! i Face sheet

(C)

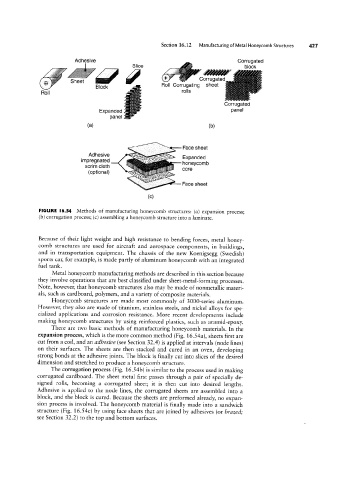

FIGURE I6.54 Methods of manufacturing honeycomb structures: (a) expansion process;

(bl corrugation process; (cl assembling a honeycomb structure into a laminate.

Because of their light weight and high resistance to bending forces, metal honey-

comb structures are used for aircraft and aerospace components, in buildings,

and in transportation equipment. The chassis of the new Koenigsegg (Swedish)

sports car, for example, is made partly of aluminum honeycomb with an integrated

fuel tank.

Metal honeycomb manufacturing methods are described in this section because

they involve operations that are best classified under sheet-metal-forming processes.

Note, however, that honeycomb structures also may be made of nonmetallic materi-

als, such as cardboard, polymers, and a variety of composite materials.

Honeycomb structures are made most commonly of 3000~series aluminum.

However, they also are made of titanium, stainless steels, and nickel alloys for spe-

cialized applications and corrosion resistance. More recent developments include

making honeycomb structures by using reinforced plastics, such as aramid-epoxy.

There are two basic methods of manufacturing honeycomb materials. In the

expansion process, which is the more common method (Fig. 16.54a), sheets first are

cut from a coil, and an adhesive (see Section 32.4) is applied at intervals (node lines)

on their surfaces. The sheets are then stacked and cured in an oven, developing

strong bonds at the adhesive joints. The block is finally cut into slices of the desired

dimension and stretched to produce a honeycomb structure.

The corrugation process (Fig. 16.54b) is similar to the process used in making

corrugated cardboard. The sheet metal first passes through a pair of specially de-

signed rolls, becoming a corrugated sheet; it is then cut into desired lengths.

Adhesive is applied to the node lines, the corrugated sheets are assembled into a

block, and the block is cured. Because the sheets are preformed already, no expan-

sion process is involved. The honeycomb material is finally made into a sandwich

structure (Fig. 16.54c) by using face sheets that are joined by adhesives (or bmzed;

see Section 322) to the top and bottom surfaces.