Page 566 - Marine Structural Design

P. 566

542 Part V Risk Assessment

(30.5)

where,

Pmr = Occurrence probability of dropped object impact

Ni = Annual number of lifts per load category i

= Probability of load dropped from crane for load category i

‘Di

PHg = Probability of equipment j being hit by falling load in category i, given that

the load is dropped

PFv = Probability of failure of equipment j given impact by load in category i

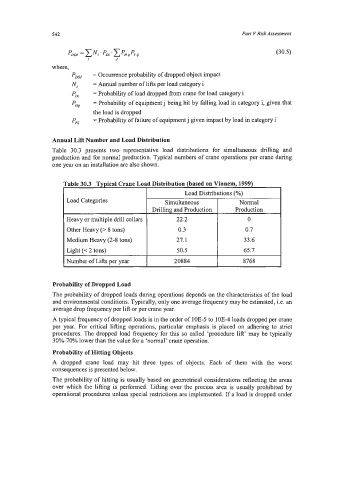

Annual Lift Number and Load Distribution

Table 30.3 presents two representative load distributions for simultaneous drilling and

production and for normal production. Typical numbers of crane operations per crane during

one year on an installation are also shown.

Load Distributions (“A)

Load Categories Simultaneous Normal

Drilling and Production Production

Heavy or multiple drill collars 22.2 0

Other Heavy (> 8 tons) 0.3 0.7

Medium Heavy (2-8 tons) 27.1 33.6

Light (c 2 tons) 50.5 65.7

Number of Lifts per year 20884 8768

Probability of Dropped Load

The probability of dropped loads during operations depends on the characteristics of the load

and environmental conditions. Typically, only one average frequency may be estimated, Le. an

average drop fiequency per lift or per crane year.

A typical frequency of dropped loads is in the order of 10E-5 to 10E-4 loads dropped per crane

per year. For critical lifting operations, particular emphasis is placed on adhering to strict

procedures. The dropped load frequency for this so called ‘procedure lift’ may be typically

30%-70% lower than the value for a ‘normal’ crane operation.

Probability of Hitting Objects

A dropped crane load may hit three types of objects. Each of them with the worst

consequences is presented below.

The probability of hitting is usually based on geometrical considerations reflecting the areas

over which the lifting is performed. Lifting over the process area is usually prohibited by

operational procedures unless special restrictions are implemented. If a load is dropped under