Page 621 - Marine Structural Design

P. 621

Chapter 34 Risk Centered Maintenance 591

System: Performed by:

Ref. Drawing no: Date:

Failure Effects

Y

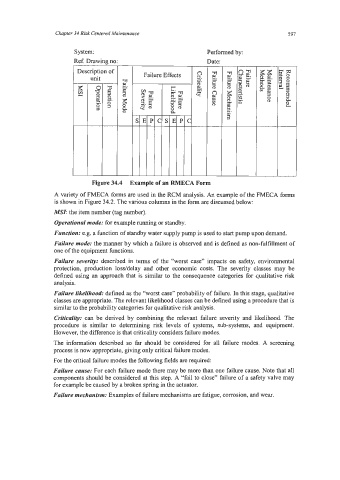

Figure 34.4 Example of an RMECA Form

A variety of FMECA forms are used in the RCM analysis. An example of the FMECA forms

is shown in Figure 34.2. The various columns in the form are discussed below:

MSI: the item number (tag number).

OperationaI mode: for example running or standby.

Function: e.g. a function of standby water supply pump is used to start pump upon demand.

Failure mode: the manner by which a failure is observed and is defined as non-hlfillment of

one of the equipment functions.

Failure severity: described in terms of the “worst case” impacts on safety, environmental

protection, production loss/delay and other economic costs. The severity classes may be

defined using an approach that is similar to the consequence categories for qualitative risk

analysis.

Failure likelihood: defined as the “worst case” probability of failure. In this stage, qualitative

classes are appropriate. The relevant likelihood classes can be defined using a procedure that is

similar to the probability categories for qualitative risk analysis.

CriticaIity: can be derived by combining the relevant failure severity and likelihood. The

procedure is similar to determining risk levels of systems, sub-systems, and equipment.

However, the difference is that criticality considers failure modes.

The information described so far should be considered for all failure modes. A screening

process is now appropriate, giving only critical failure modes.

For the critical failure modes the following fields are required:

Failure came: For each failure mode there may be more than one failure cause. Note that a11

components should be considered at this step. A “fail to close” failure of a safety valve may

for example be caused by a broken spring in the actuator.

Failure mechanism: Examples of failure mechanisms are fatigue, corrosion, and wear.