Page 143 - Materials Science and Engineering An Introduction

P. 143

4.5 Dislocations—Linear Defects • 115

C Al A Cu

C Al = * 100

C Al A Cu + C Cu A Al

Tutorial Video: = (97)(63.55 g/mol) * 100

How to (97)(63.55 g/mol) + (3)(26.98 g/mol)

Convert from

Atom Percent = 98.7 at%

to Weight and

Percent

C Cu A Al

C Cu = * 100

C Cu A Al + C Al A Cu

(3)(26.98 g/mol)

= * 100

(3)(26.98 g/mol) + (97)(63.55 g/mol)

= 1.30 at%

Miscellaneous Imperfections

4.5 DISLOCATIONS—LINEAR DEFECTS

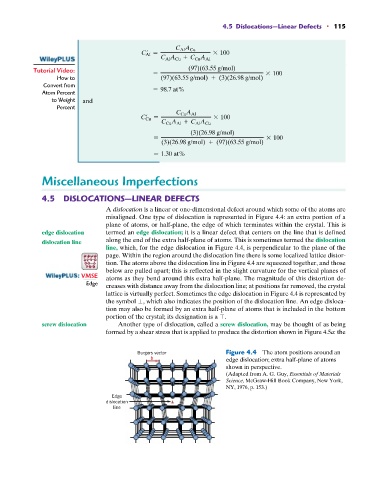

A dislocation is a linear or one-dimensional defect around which some of the atoms are

misaligned. One type of dislocation is represented in Figure 4.4: an extra portion of a

plane of atoms, or half-plane, the edge of which terminates within the crystal. This is

edge dislocation termed an edge dislocation; it is a linear defect that centers on the line that is defined

along the end of the extra half-plane of atoms. This is sometimes termed the dislocation

dislocation line

line, which, for the edge dislocation in Figure 4.4, is perpendicular to the plane of the

page. Within the region around the dislocation line there is some localized lattice distor-

tion. The atoms above the dislocation line in Figure 4.4 are squeezed together, and those

below are pulled apart; this is reflected in the slight curvature for the vertical planes of

: VMSE atoms as they bend around this extra half-plane. The magnitude of this distortion de-

Edge creases with distance away from the dislocation line; at positions far removed, the crystal

lattice is virtually perfect. Sometimes the edge dislocation in Figure 4.4 is represented by

the symbol #, which also indicates the position of the dislocation line. An edge disloca-

tion may also be formed by an extra half-plane of atoms that is included in the bottom

portion of the crystal; its designation is a . #

screw dislocation Another type of dislocation, called a screw dislocation, may be thought of as being

formed by a shear stress that is applied to produce the distortion shown in Figure 4.5a: the

Burgers vector Figure 4.4 The atom positions around an

b edge dislocation; extra half-plane of atoms

shown in perspective.

(Adapted from A. G. Guy, Essentials of Materials

Science, McGraw-Hill Book Company, New York,

NY, 1976, p. 153.)

Edge

dislocation

line