Page 108 - Mechanical Engineer's Data Handbook

P. 108

APPLIED MECHANICS 97

Design of gears Tangential force on gears F, = F cos r#J

Separating force on gears F, = F, tan q5

The design of gears is complex and it is recommended

FIDI

that British Standards (or other similar sources) be Torque on driver gear TI =-

consulted. 2

See BS 436 for the design of gears and BS 1949 for FID,

permissible stresses. Torque on driven gear T, =- 2

. N, D, n

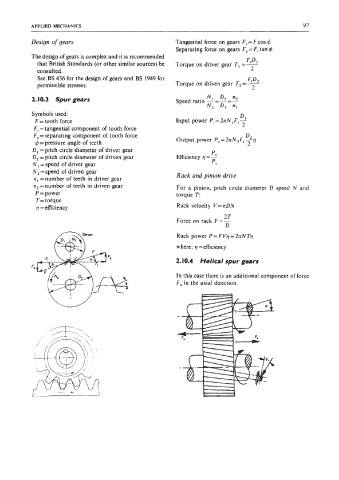

2.10.3 Spur gears Speed ratio ---=A

N2 D, n,

Symbols used: D

F = tooth force Input power Pi = 271N , F, 2

F, = tangential component of tooth force

F, = separating component of tooth force D

r#J =pressure angle of teeth Output power P,=2nN2F,~q

2

D, =pitch circle diameter of driver gear

Po

D, =pitch circle diameter of driven gear Efficiency q = -

N, =speed of driver gear pi

N, =speed of driven gear Rack and pinion drive

n, =number of teeth in driver gear

n2 =number of teeth in driven gear For a pinion, pitch circle diameter D speed N and

P =power torque T:

T= torque

9 =efficiency Rack velocity V=nDN

2T

Force on rack F=-

D

Rack power P = F Vq = 2nN Tq

where: 9 =efficiency.

2.10.4 Helical spur gears

In this case there is an additional component of force

Fa in the axial direction.