Page 16 - Mechanical Engineer's Data Handbook

P. 16

STRENGTHS OF MATERIALS 5

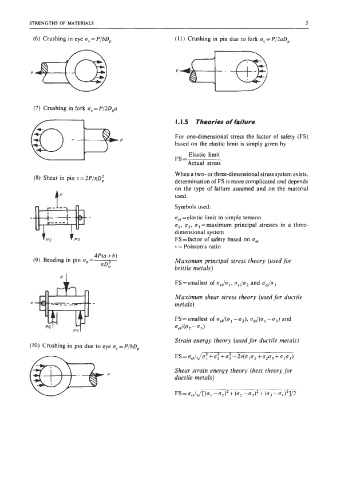

(6) Crushing in eye a, = P/bD, (1 1) Crushing in pin due to fork a, = P/2aD,

p E @

(7) Crushing in fork uc = P/2Dpa

I. I .5 Theories of failure

@T+-jLp

For one-dimensional stress the factor of safety (FS)

based on the elastic limit is simply given by

Elastic limit

FS =

Actual stress‘

When a two- or three-dimensional stress system exists,

(8) Shear in pin r=2P/7rD; determination of FS is more complicated and depends

sp on the type of failure assumed and on the material

used.

Symbols used:

ael =elastic limit in simple tension

at, az, a,=maximum principal stresses in a three-

dimensional system

tPl2 i Pi2 FS = factor of safety based on a,,

v = Poisson’s ratio

4P(a + b)

(9) Bending in pin ab=- Maximum principal stress theory (used for

ZDP”

brittle metals)

PI

FS =smallest of ael/uI, aeJa2 and ael/a3

Maximum shear stress theory (used for ductile

metals)

FS = smallest of ae,/(ul -a2), aeI/(aI - a3) and

a,,/(a, -03)

Strain energy theory (used for ductile metals)

(10) Crushing in pin due to eye a, = P/bDp

n FS = a,,/Ja: + a: + a: - 2v(alaz +a2a, + a,a3)

Shear strain energy theory (best theory for

ductile metals)

W