Page 19 - Mechanical Engineer's Data Handbook

P. 19

8 MECHANICAL ENGINEER’S DATA HANDBOOK

1.2 Strength of fasteners

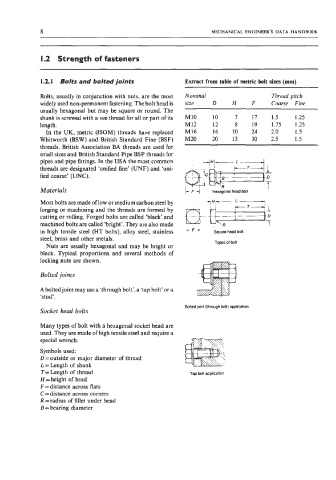

I .2. I Bolts and bolted joints Extract from table of metric bolt sizes (mm)

Bolts, usually in conjunction with nuts, are the most Nominal Thread pitch

widely used non-permanent fastening. The bolt head is size D H F Coarse Fine

usually hexagonal but may be square or round. The

shank is screwed with a vee thread for all or part of its M 10 10 7 17 1.5 1.25

length. M12 12 8 19 1.75 1.25

In the UK, metric (ISOM) threads have replaced M16 16 10 24 2.0 1.5

Whitworth (BSW) and British Standard Fine (BSF) M20 20 13 30 2.5 1.5

threads. British Association BA threads are used for

small sizes and British Standard Pipe BSP threads for

pipes and pipe fittings. In the USA the most common

threads are designated ‘unified fine’ (UNF) and ‘uni-

fied coarse’ (UNC).

Materials F--/ Hexagonal head bolt

Most bolts are made of low or medium carbon steel by

forging or machining and the threads are formed by

cutting or rolling. Forged bolts are called ‘black’ and D

machined bolts are called ‘bright’. They are also made

in high tensile steel (HT bolts), alloy steel, stainless - F- Square head bolt

steel, brass and other metals.

Nuts are usually hexagonal and may be bright or Types of bolt

black. Typical proportions and several methods of

locking nuts are shown.

Bolted joints

A bolted joint may use a ‘through bolt’, a ‘tap bolt’ or a

‘stud’.

Bolted joint (through bolt) application

Socket head bolts

Many types of bolt with a hexagonal socket head are

used. They are made of high tensile steel and require a

special wrench.

Symbols used:

D = outside or major diameter of thread

L = Length of shank

T= Length of thread Tap bolt application

H = height of head

F=distance across flats

C = distance across corners

R = radius of fillet under head

B = bearing diameter