Page 23 - Mechanical Engineer's Data Handbook

P. 23

12 MECHANICAL ENGINEER'S DATA HANDBOOK

I

+,MI

I

\

I

f

P 0 I

P

P

Efficiency of joint:

least of P P P P

PI2 I]. = 4x1~%

QpPt

P

Butt joint

PI2

The rivet is in 'double shear', therefore P, =z,nD2/2

per row.

I

Crushing stress 3D2

In practice, P, is nearer to TJC-.

8

Q, = P/Dt

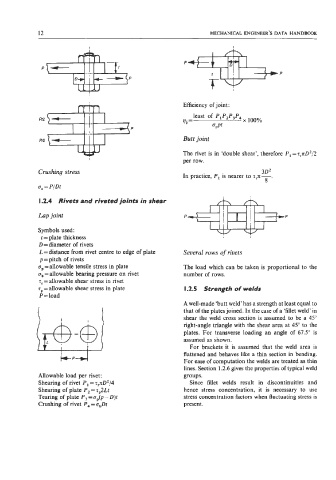

I .2.4 Rivets and riveted joints in shear

Lap joint

Symbols used:

t = plate thickness

D=diameter of rivets

L=distance from rivet centre to edge of plate Several rows of rivets

p=pitch of rivets

oP = allowable tensile stress in plate The load which can be taken is proportional to the

ob =allowable bearing pressure on rivet number of rows.

t, = allowable shear stress in rivet

T~ = allowable shear stress in plate 1.2.5 Strength of welds

P =load

A well-made 'butt weld' has a strength at least equal to

that of the plates joined. In the case of a 'fillet weld' in

shear the weld cross section is assumed to be a 45"

right-angle triangle with the shear area at 45" to the

plates. For transverse loading an angle of 67.5" is

assumed as shown.

For brackets it is assumed that the weld area is

flattened and behaves like a thin section in bending.

For ease of computation the welds are treated as thin

lines. Section 1.2.6 gives the properties of typical weld

Allowable load per rivet: groups.

Shearing of rivet P, =T,RD~/~ Since fillet welds result in discontinuities and

Shearing of plate P, = tp2Lt hence stress concentration, it is necessary to use

Tearing of plate P, = ap(p - D)t stress concentration factors when fluctuating stress is

Crushing of rivet P, = abDt present.