Page 24 - Mechanical Engineer's Data Handbook

P. 24

STRENGTHS OF MATERIALS 13

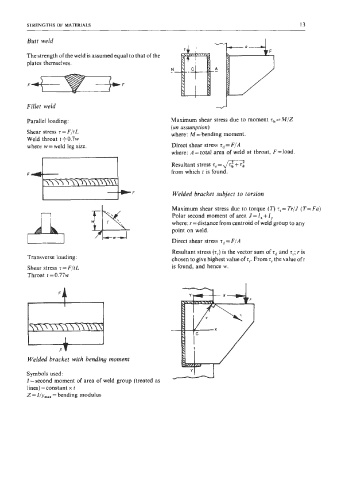

Butt weld

The strength of the weld is assumed equal to that of the

plates themselves.

Fillet weld

Parallel loading: Maximum shear stress due to moment 7bs M/Z

(an assumption)

Shear stress 7 = F/tL where: M= bending moment.

Weld throat t =0.7w

where w = weld leg size. Direct shear stress T~ = F/A

where: A = total area of weld at throat, F =load.

Resultant stress 7r = J‘m

from which t is found.

Welded bracket subject to torsion

Maximum shear stress due to torque (T) z,= Tr/J (T=Fa)

Polar second moment of area J = I, + I,

where: r = distance from centroid of weld group to any

point on weld.

Direct shear stress sd = F/A

is

r

Resultant stress (T~) the vector sum of T~ and T~; is

Transverse loading: chosen to give highest value of T~. From T, the value oft

Shear stress 7 = F/tL is found, and hence w.

Throat t = 0.77~

I

,n\\\’m

1

Symbols used :

I=second moment of area of weld group (treated as

lines) = constant x t

Z = l/ymax = bending modulus