Page 214 - Mechanical Engineer's Data Handbook

P. 214

202 MECHANICAL ENGINEER'S DATA HANDBOOK

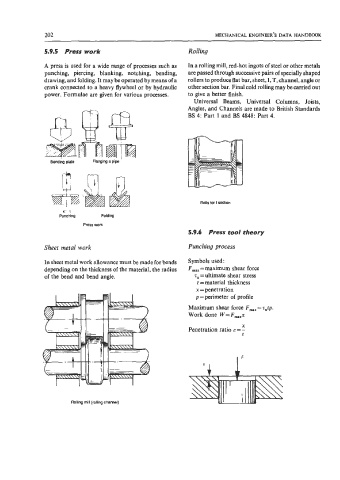

5.9.5 Press work Rolling

A press is used for a wide range of processes such as In a rolling mill, red-hot ingots of steel or other metals

punching, piercing, blanking, notching, bending, are passed through successive pairs of specially shaped

drawing, and folding. It may be operated by means of a rollers to produce flat bar, sheet, I, T, channel, angle or

crank connected to a heavy flywheel or by hydraulic other section bar. Final cold rolling may be camed out

power. Formulae are given for various processes. to give a better finish.

Universal Beams, Universal Columns, Joists,

Angles, and Channels are made to British Standards

BS 4: Part 1 and BS 4848: Part 4.

Bending plate Flanging a pipe

Rolls for I section

=-

Punching Folding

Press work

5.9.6 Press tool theory

Sheet metal work Punching process

In sheet metal work allowance must be made for bends Symbols used:

depending on the thickness of the material, the radius F,,, = maximum shear force

of the bend and bend angle. 7u =ultimate shear stress

t =material thickness

x = penetration

p = perimeter of profile

Maximum shear force F,,, = 7.t~.

Work done W= Fmaxx

X

Penetration ratio c = -

t

Rolling mill (rolling channel)