Page 217 - Mechanical Engineer's Data Handbook

P. 217

MANUFACTURING TECHNOLOGY 205

L

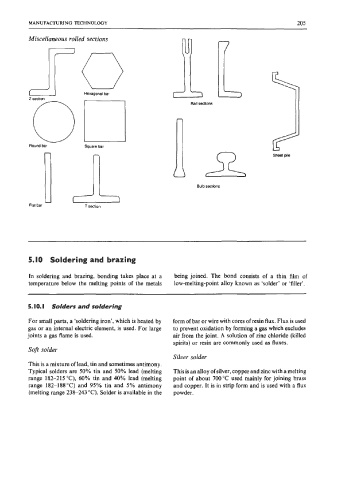

Miscellaneous rolled sections

Hexagonal ba~

n

2 section Rail sections

z

Round bar Square bar

Shea pile

Bulb -ions

Flat bai T section

5.10 Soldering and brazing

In soldering and brazing, bonding takes place at a being joined. The bond consists of a thin film of

temperature below the melting points of the metals low-melting-point alloy known as 'solder' or 'filler'.

5. IO. I Solders and soldering

For small parts, a 'soldering iron', which is heated by form of bar or wire with cores of resin flux. Flux is used

gas or an internal electric element, is used. For large to prevent oxidation by forming a gas which excludes

joints a gas flame is used. air from the joint. A solution of zinc chloride (killed

spirits) or resin are commonly used as fluxes.

Soji solder

Silver solder

This is a mixture of lead, tin and sometimes antimony.

Typical solders are 50% tin and 50% lead (melting This is an alloy of silver, copper and zinc with a melting

range 182-21SoC), 60% tin and 40% lead (melting point of about 700°C used mainly for joining brass

range 182-188°C) and 95% tin and 5% antimony and copper. It is in strip form and is used with a flux

(melting range 238-243 "C). Solder is available in the powder.