Page 220 - Mechanical Engineer's Data Handbook

P. 220

208 MECHANICAL ENGINEER'S DATA HANDBOOK

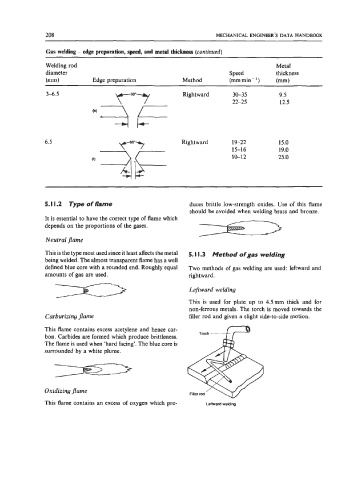

Gas welding - edge preparation, speed, and metal thickness (continued)

Welding rod Metal

diameter Speed thickness

(mm) Edge preparation Method (mmmin-') (mm)

3-6.5 Rightward 30-35 9.5

22-25 12.5

3 E

4cf

6.5 Rightward 19-22 15.0

y--"07 15-16 19.0

10-12 25.0

5.1 1.2 Type of flame duces brittle low-strength oxides. Use of this flame

should be avoided when welding brass and bronze.

It is essential to have the correct type of flame which

depends on the proportions of the gases.

Neutral flame

This is the type most used since it least affects the metal 5. I I .3 Method of gas welding

being welded. The almost transparent flame has a well

defined blue core with a rounded end. Roughly equal Two methods of gas welding are used: leftward and

amounts of gas are used. rightward.

Leftward welding

This is used for plate up to 4.5mm thick and for

non-ferrous metals. The torch is moved towards the

Carburizing flame filler rod and given a slight side-to-side motion.

This flame contains excess acetylene and hence car-

bon. Carbides are formed which produce brittleness.

The flame is used when 'hard facing'. The blue core is

surrounded by a white plume.

Oxidizing flame

This flame contains an excess of oxygen which pro- Lettward welding