Page 223 - Mechanical Engineer's Data Handbook

P. 223

--

MANUFACTURING TECHNOLOGY 21 1

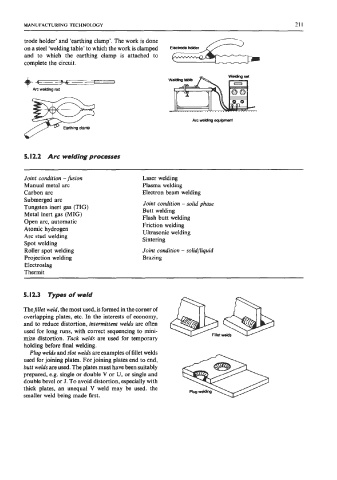

trode holder’ and ‘earthing clamp’. The work is done

on a steel ‘welding table’ to which the work is clamped E M

and to which the earthing clamp is attached to

complete the circuit.

B.-

Earthing

clamp

5.12.2 Arc welding processes

Joint condition -fusion Laser welding

Manual metal arc Plasma welding

Carbon arc Electron beam welding

Submerged arc Joint condition - solid phase

Tungsten inert gas (TIG) Butt welding

Metal inert gas (MIG)

Open arc, automatic Flash butt welding

Atomic hydrogen Friction welding

Arc stud welding Ultrasonic welding

Sintering

Spot welding

Roller spot welding Joint condition - solid/liquid

Projection welding Brazing

Electroslag

Thermit

and to reduce distortion, intermittent welds are often @&

5.12.3

Types of weld

Thefillet weld, the most used, is formed in the corner of

overlapping plates, etc. In the interests of economy,

used for long runs, with correct sequencing to mini-

mix distortion. Tack welds are used for temporary Fillet wekls

holding before final welding.

Plug welds and slot welds are examples of fillet welds

used for joining plates. For joining plates end to end,

butt welds are used. The plates must have been suitably

prepared, e.g. single or double V or U, or single and

double bevel or J. To avoid distortion, especially with

thick plates, an unequal V weld may be used. the

smaller weld being made first.